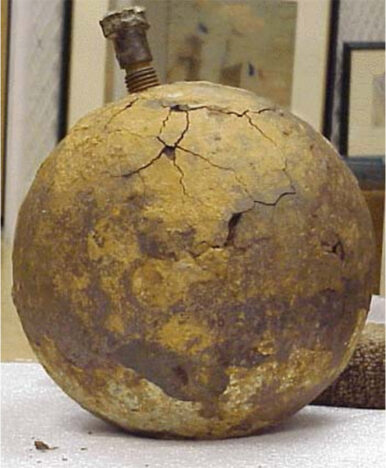

When the sea claimed USS Monitor in 1862, the world lost an irreplaceable piece of cultural heritage. Fortunately, 140 years later, one-fifth of the ship was recovered from the depths of the Atlantic. These one-of-a-kind artifacts now reside within the Batten Conservation Complex at The Mariners’ Museum and Park, where they are undergoing conservation. In partnership with NOAA’s Monitor National Marine Sanctuary, we are proud to be the stewards of this revolutionary vessel.

USS Monitor represents the world’s largest marine archaeological metals conservation project. More than 210 tons of material were excavated from Monitor’s wreck site, all requiring care. Among the historically significant objects recovered are Monitor‘s revolving gun turret, two Dahlgren guns, and its steam propulsion engine. The Museum’s archaeological conservators tackle tons of challenges every day, working with materials ranging all over like iron, copper, wood, rope, fabric, and rubber.

Objects recovered from the USS Monitor wreck site:

Research

Conservation involves looking for answers to lots of questions: What material is an object made of? How or why is it degrading? What can we do about it? Research questions help the Conservation team learn more about the artifacts and make wise treatment decisions.

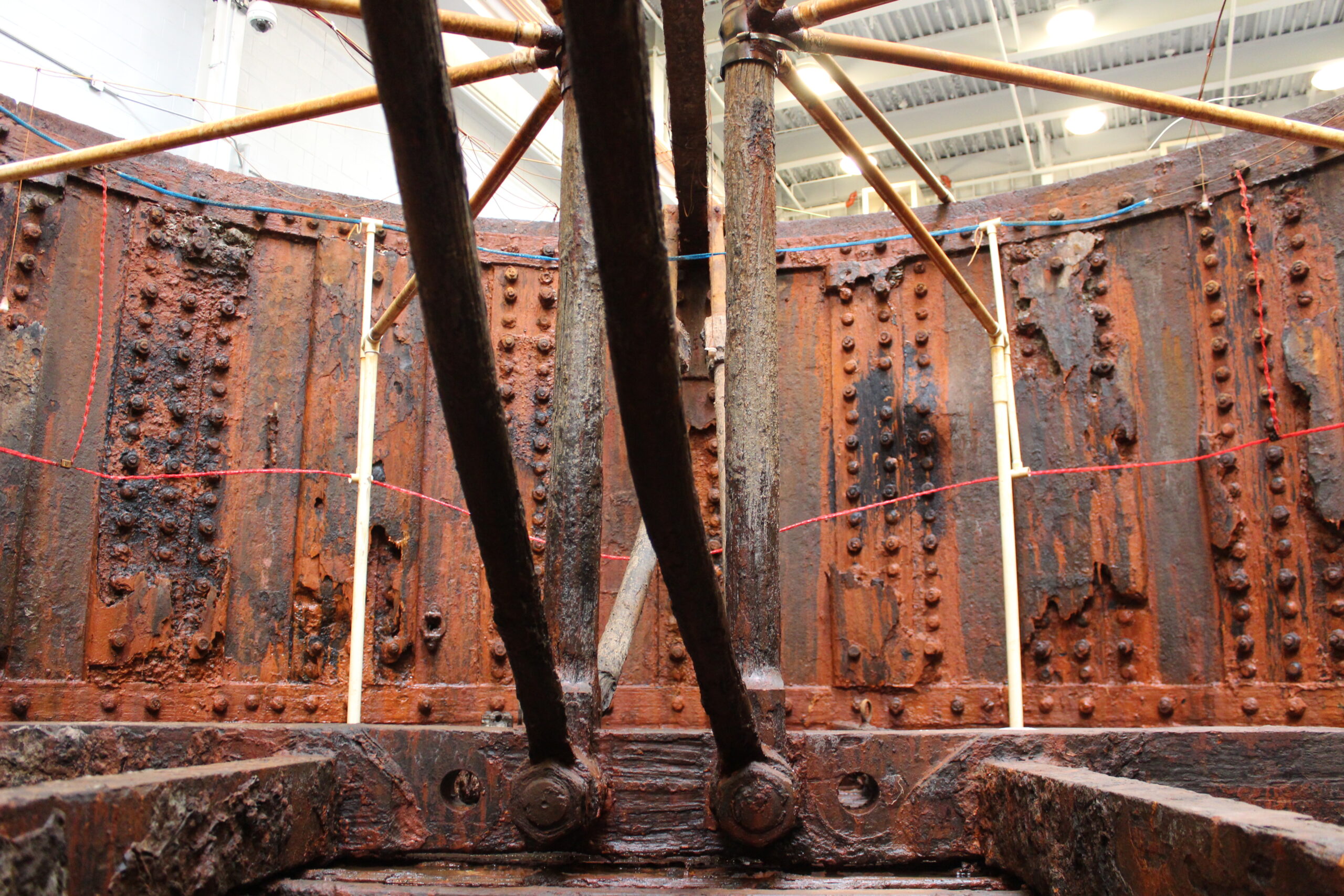

Turret

As the first of its kind ever to be installed on a ship, USS Monitor’s 115-ton revolving gun turret represents a major technological advancement that changed the course of naval architecture and warfare. Since its recovery in 2002, the Museum has worked to preserve and stabilize the turret and the many objects recovered inside through conservation, the archaeological record, and 3-D modeling.

Turret Project Highlights

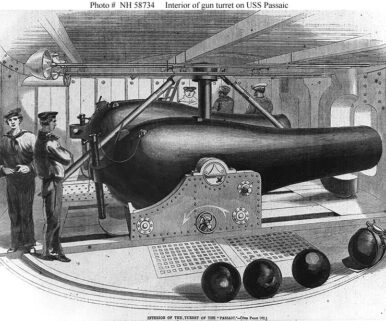

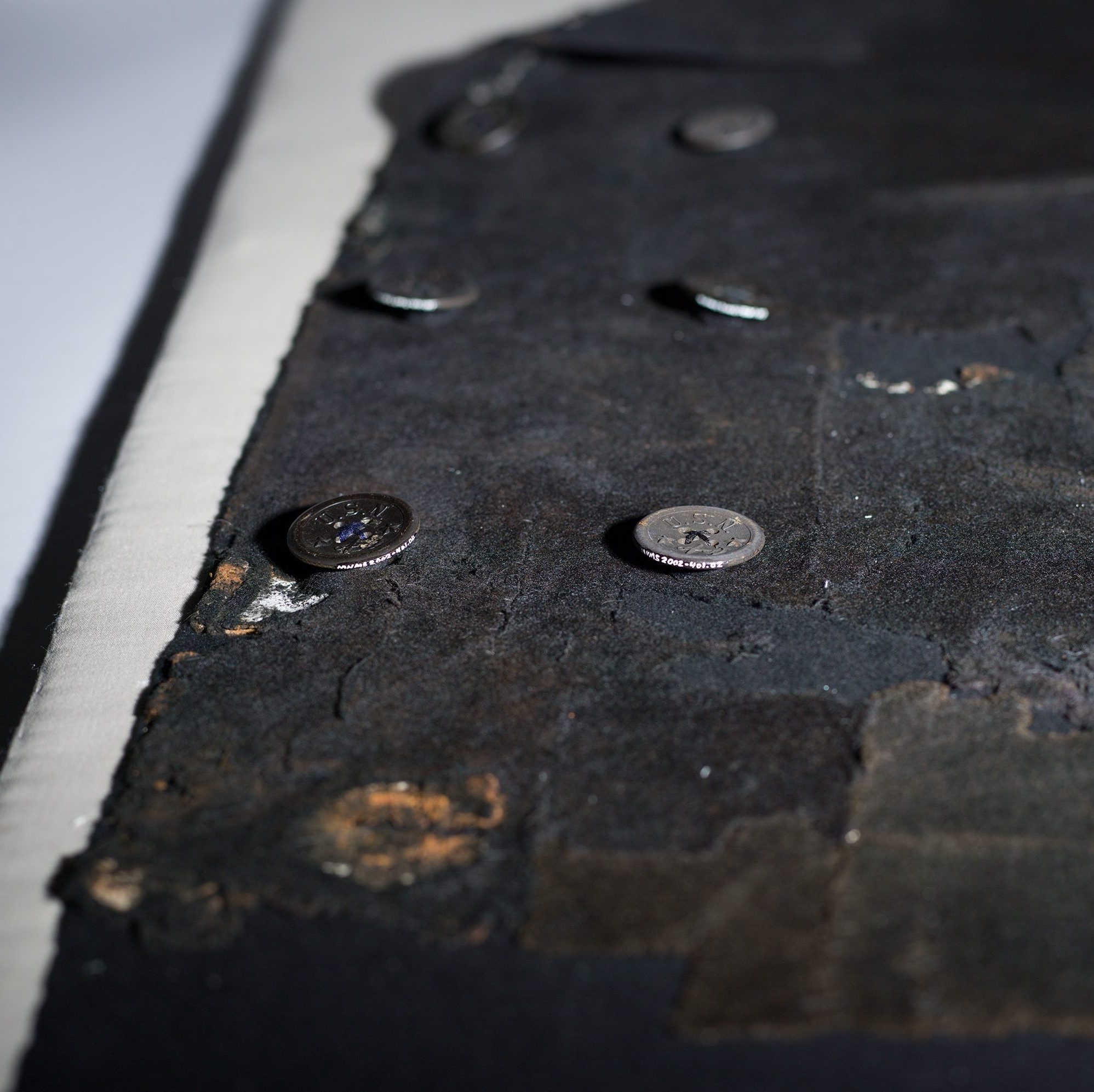

Personal Effects

Engraved silverware, clothing, and footwear are among the many personal effects left behind by Monitor’s crew as they rushed to escape their sinking ship. Unfortunately, two sailors perished in the turret. Their remains were discovered during excavation. Some of the most relatable artifacts of the Monitor Collection were in these sailors’ pockets – coins, a key, and a pocket knife. A thick wool coat was found nearby but not associated with the two sailors. This coat was recovered in about 150 pieces! After conservation, many of these objects are now on display in the Museum, offering small glimpses into Monitor’s crew members’ lives.

Personal Effects Project Highlights

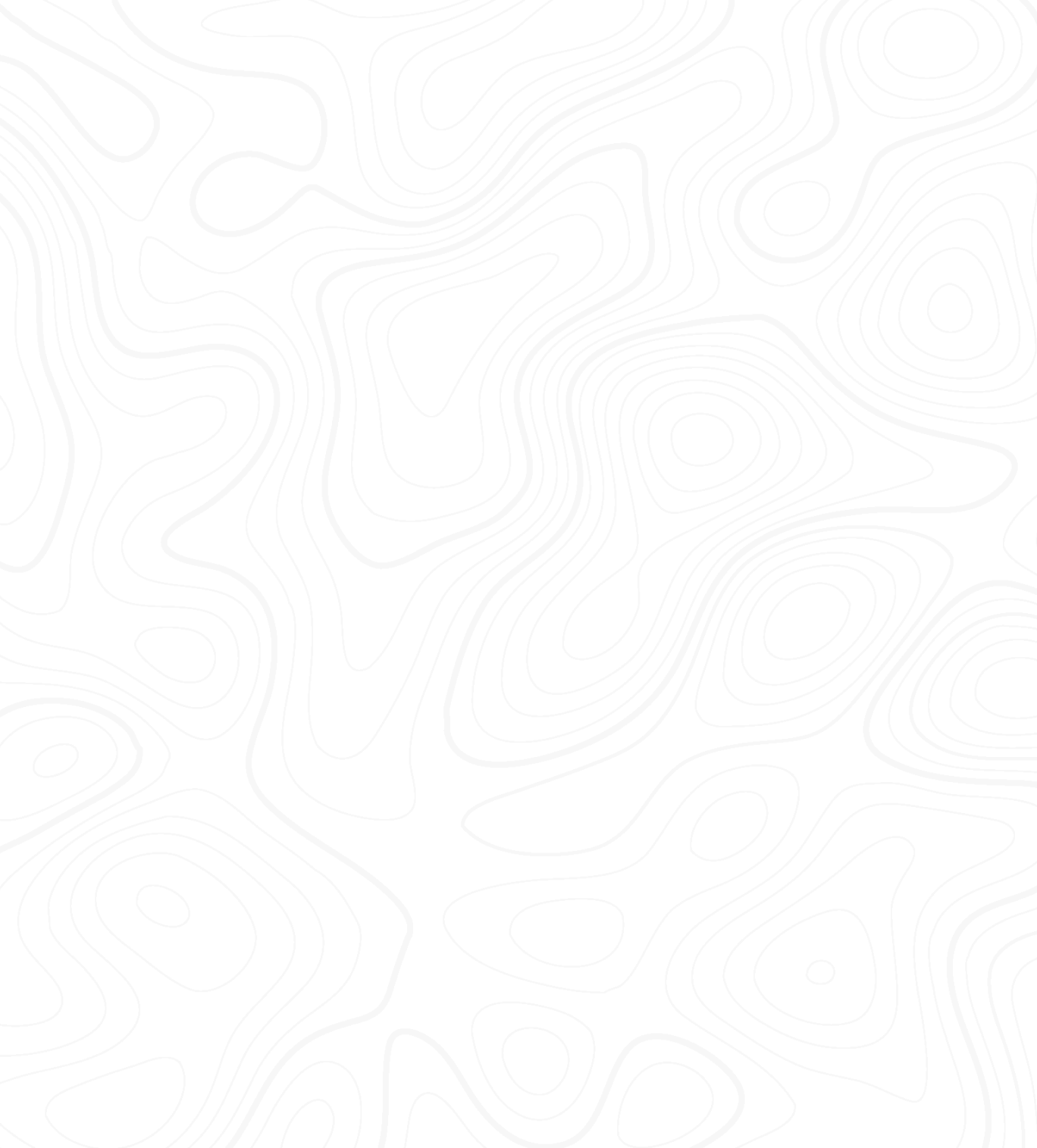

Dahlgren Guns & Carriage

USS Monitor mounted two XI-Inch Dahlgren shell guns as its primary armament. When the ship’s turret was recovered, these 16,000-pound behemoths were still inside! The gun carriages – a unique design allowing the guns to fire from Monitor’s first-of-its-kind rotating turret – were also recovered, along with numerous tools used to clean, load, and fire the guns. The historical significance of these objects is matched only by the complexity of their conservation. These guns required cleaning to remove concretion from inside the bores. Custom equipment was designed and created to clean the largest marine archaeological, smoothbore cast-iron guns ever conserved.

Dahlgren Guns & Carriage Project Highlights

Machinery

USS Monitor’s steam engine room represents the earliest and most complete steamship engine room ever archaeologically raised. This includes John Ericsson’s 20-ton vibrating side-lever-trunked dual steam engine, used to propel the ironclad. The engine’s unique, compact design enabled it to be mounted below the waterline and away from enemy fire. It is the only known example of this type of marine engine in the world! Also from the engine room are two direct-acting Worthington steam-powered water pumps, the oldest surviving Worthington examples. The collection of these artifacts enables us to understand what life would have been like in the engine room, and through conservation, The Mariners’ team can share that experience with the public.

Machinery Project Highlights

Skeg and Hull Structure

In addition to the artifacts visible in the Wet Lab, other objects like hull plates, bulkheads (watertight walls in ships), and the turret control lever are stored in seven outdoor tanks affectionately named the “Tank Farm.” These objects are critical to understanding the ship’s construction. Monitor’s skeg is one of the most unique objects stored in the Tank Farm. What’s a skeg, you might ask? It’s the section of the back (stern) of a vessel that stabilizes the rudder and propeller. Monitor’s skeg beam is 25 feet long and weighs 3,800 pounds!

Skeg and Hull Structure Project Highlights

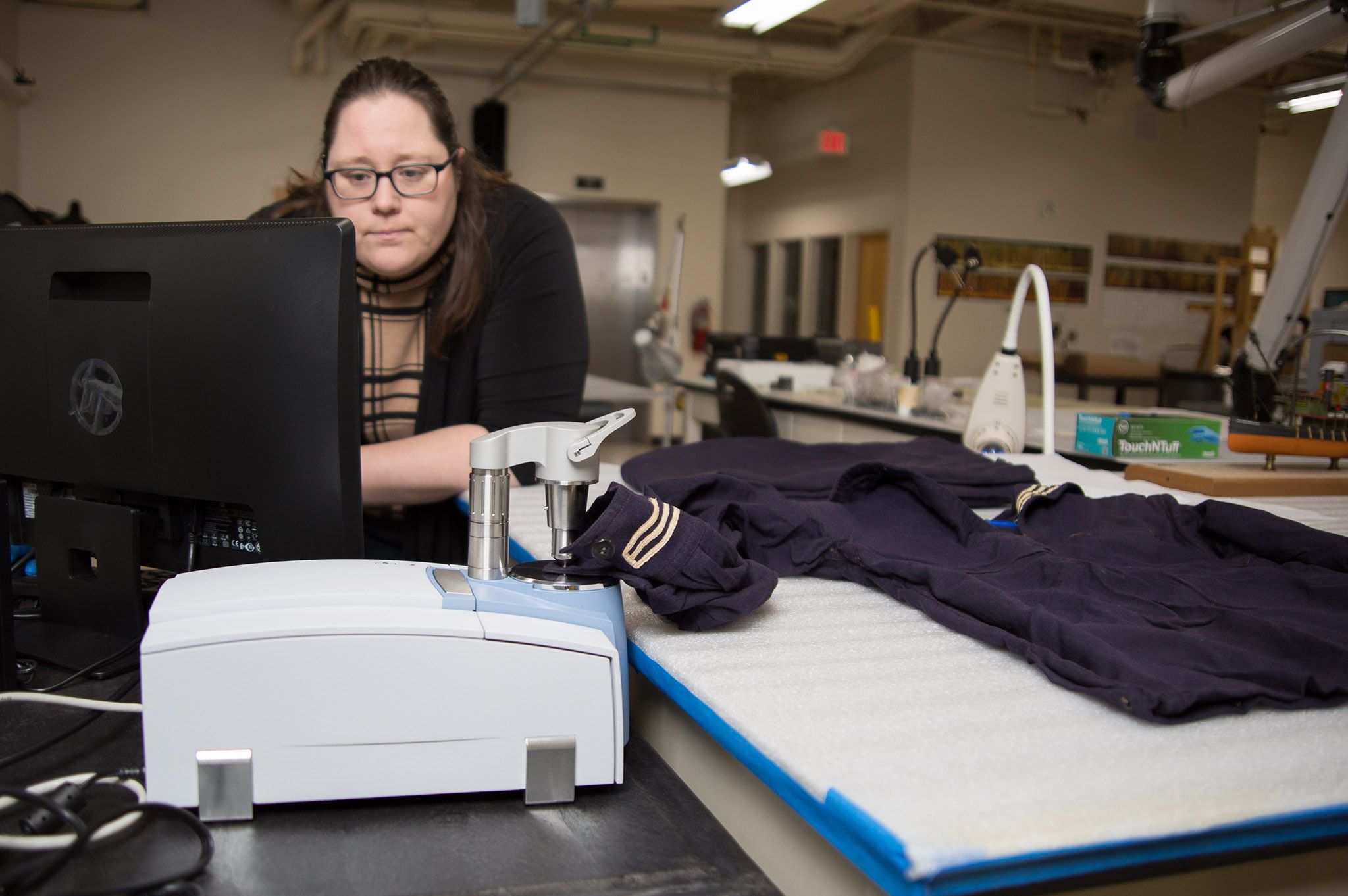

Research

Conservation involves looking for answers to lots of questions: What material is an object made of? How or why is it degrading? What can we do about it? Research questions help the Conservation team learn more about the artifacts and make wise treatment decisions. We rely on a great team of Museum scientific staff, external partners, and various analytical tools to find the answers. Scientific analysis is invaluable to moving conservation projects ahead.