Hello Everyone! I know that lately the blog has been abounding with news about new additions to the conservation team, but prepare for a little Déjà vu, as I’m writing this post to introduce myself as the newest member. My name is Laurie King, and I joined the team at the beginning of April as an Assistant Conservator. My main focus will be researching techniques for using solid CO2 (or Dry Ice Blasting) to remove corrosion from USS Monitor objects. I am a recent graduate from Cardiff University, and prior to that I actually spent my free time as a conservation volunteer with the USS Monitor Center. I am so thrilled to be back and to be working on the Monitor!

As long time readers will know, the removal of corrosion from metals can be a long process, involving a lot of detailed and time consuming work. The removal of corrosion isn’t just so the object will look nice and to reveal surface details; if corrosion remains on the surface it can trap salts in the object and cause corrosion in the future! When it comes to USS Monitor objects, this corrosion can be inches thick in some areas, making it a very painstaking process to remove the corrosion with smaller tools, like scalpels, dental tools, or air scribes. This is especially true when working on something as large as the turret or the gun carriages!

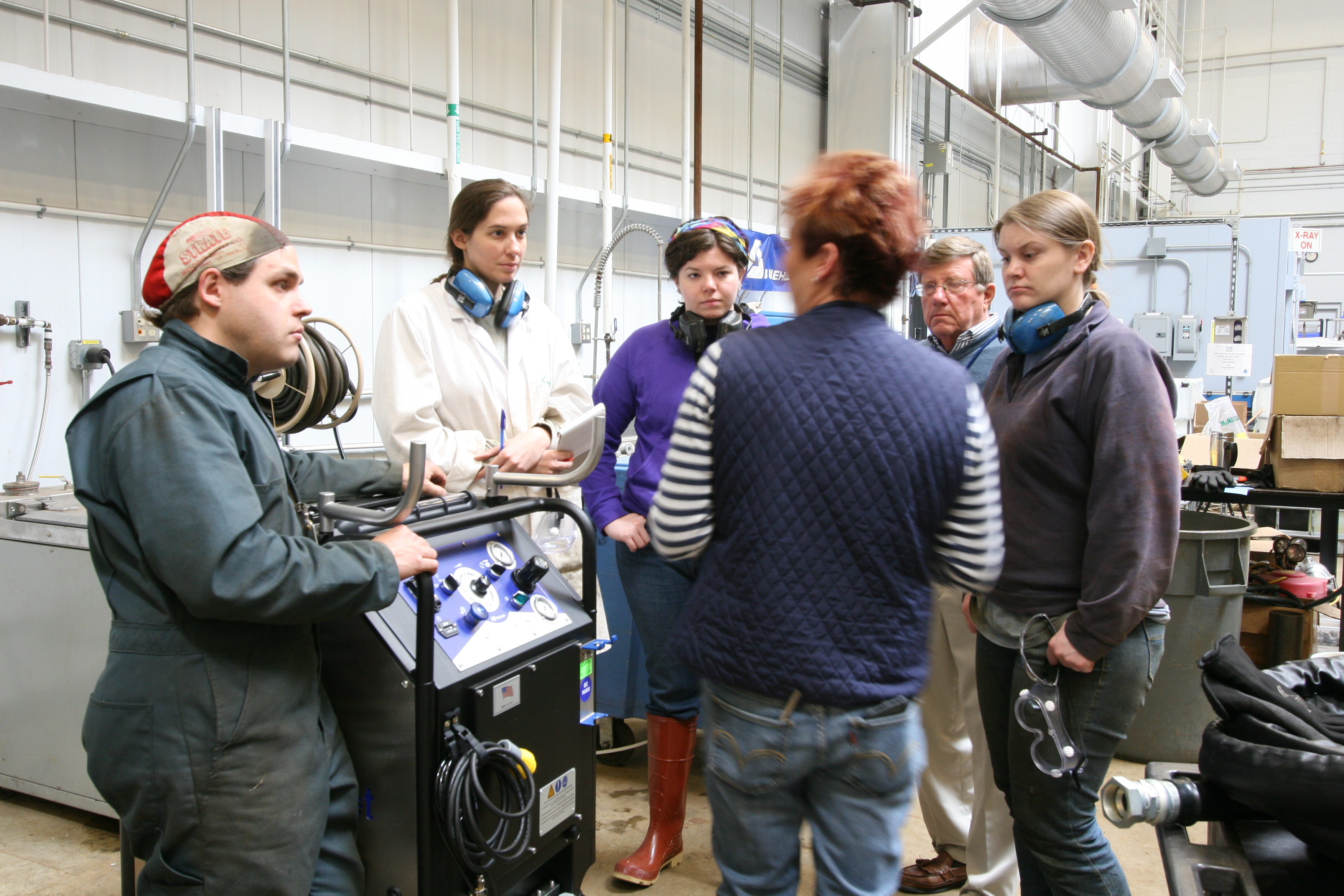

The team getting training on use of the Dry Ice Blasting Machine

The new method we’ll be implementing is the use of Dry Ice Blasting to remove corrosion. Some of you may remember that the team tested out the use of Dry Ice Blasting back in 2013 (see here). Since then, Will Hoffman has been researching the effectiveness of Dry Ice Blasting for wrought iron objects. The research provided such positive results that I have been hired on to treat a number of wrought iron objects, and research if Dry Ice Blasting could be used for cast iron and copper alloys as well.

Laurie trying out Dry Ice Blasting

Dry Ice Blasting uses pressurized air with solid carbon dioxide (CO2) as an abrasive. We’re lucky enough to be using a SDI Select 60 from ColdJet, which allows for a wide range of settings in air pressure and CO2 particle size. Dry Ice Blasting works fairly similarly to other abrasive cleaning methods. The pressurized air moves small CO2 particles as high speeds through a hose and nozzle controlled by the user. The force of the CO2 particles striking the surface removes the corrosion from the surface. The disadvantage to other kinds of abrasive cleaning, like aluminum or walnut shells, is that the abrasive particles are left over after treatment and have to be cleaned away. But, the great thing about Dry Ice Blasting is that the solid CO2 sublimates after impact, meaning there is no waste product after treatment! So this is a very exciting development for us, since it means that we will be able to use Dry Ice Blasting to better conserve a lot of different objects on the USS Monitor. Plus it is a lot of fun to use!

Elsa and Will working on the interior of the gun carriage.

Last week we had a day of training for the new members on using the Dry Ice Blasting, so we could get an idea of what the machine can do. We were all able to test out the Dry Ice Blasting on our old friend the port gun carriage, and as you can see the results are fantastic. We were able to remove a significant amount of corrosion, and in only a few hours! I think we all agreed that we’re going to have a lot of fun using this method.

Kate Dry Ice Blasting away!