When Chris and I came up with our assembly plan we were working without any sort of advice from Oracle so we decided to mount the forward crossbeam first. We would later learn from Chris Sitzenstock that the Oracle team typically assembled the three central structures first and then lowered them onto the hulls as a unit. Obviously we managed to get everything together without this knowledge, but knowing Oracle’s process helped ease the installation of the stern crossbeam.

To give ourselves room to work we shifted the hulls, central pod and stern crossbeam to one end of the gallery and pushed the hulls as close to the walls as possible—which made getting in and out of the Administration offices interesting to say the least.

We initially moved the forward crossbeam into place with the gantries but felt they might not lift the crossbeam high enough. Using them also meant we’d have to disassemble them after the lift and we wanted to avoid that process at all costs–we had already disassembled them once to get them into the building and it wasn’t easy.

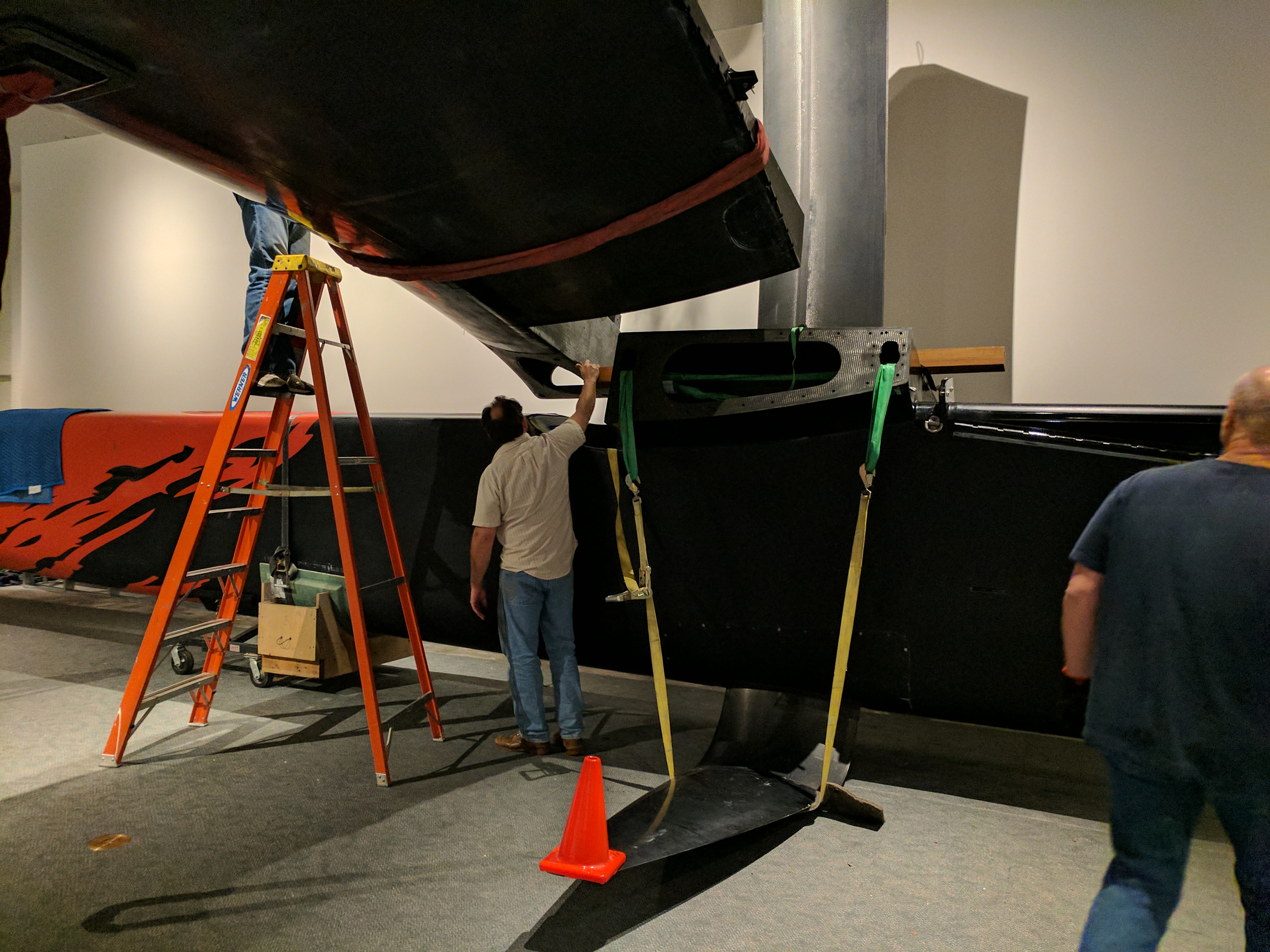

The forward crossbeam only weighs about 2200 lbs so we were confident we could use the roof trusses to lift the piece. We hung chain falls from the ceiling and raised the crossbeam about seven feet. We then moved the hulls into place and had to spend the next hour or so rigging new supports for the foils. When we mounted the foils we used the holes in the hull connection point to hang the daggerboards so we could easily move the hulls around without having to constantly re-rig the foils. Once the foils were stabilized we lowered the forward crossbeam into place. The entire process was fairly straightforward but took five or six hours to accomplish.

The difficult part began after the crossbeam was lowered into position. I climbed into the port hull and discovered that the crossbeam and hull were about ½” out of alignment. Achieving perfect alignment was an exercise in complete frustration and took several hours to accomplish. I imagine this is where Oracle’s assembly order might have made things easier for us.

A team of four people outside—with me inside the hull below the connection point taking pictures with my phone and providing verbal coaching—had to make minute adjustments by raising or lowering the bow or stern, canting the hull to port or starboard, and twisting the hull by pulling the bow in or pushing the stern out. Very slowly we reduced the offset to about a 1/16th of an inch (which still wouldn’t allow the hardware to seat correctly). Perfect alignment was finally achieved by putting a ratchet strap around the connection point between the hull and crossbeam and putting a little tension on the joint which allowed me to slip the hardware into position. Luckily, the lessons we learned on the port hull made the alignment of the starboard hull easier to achieve.