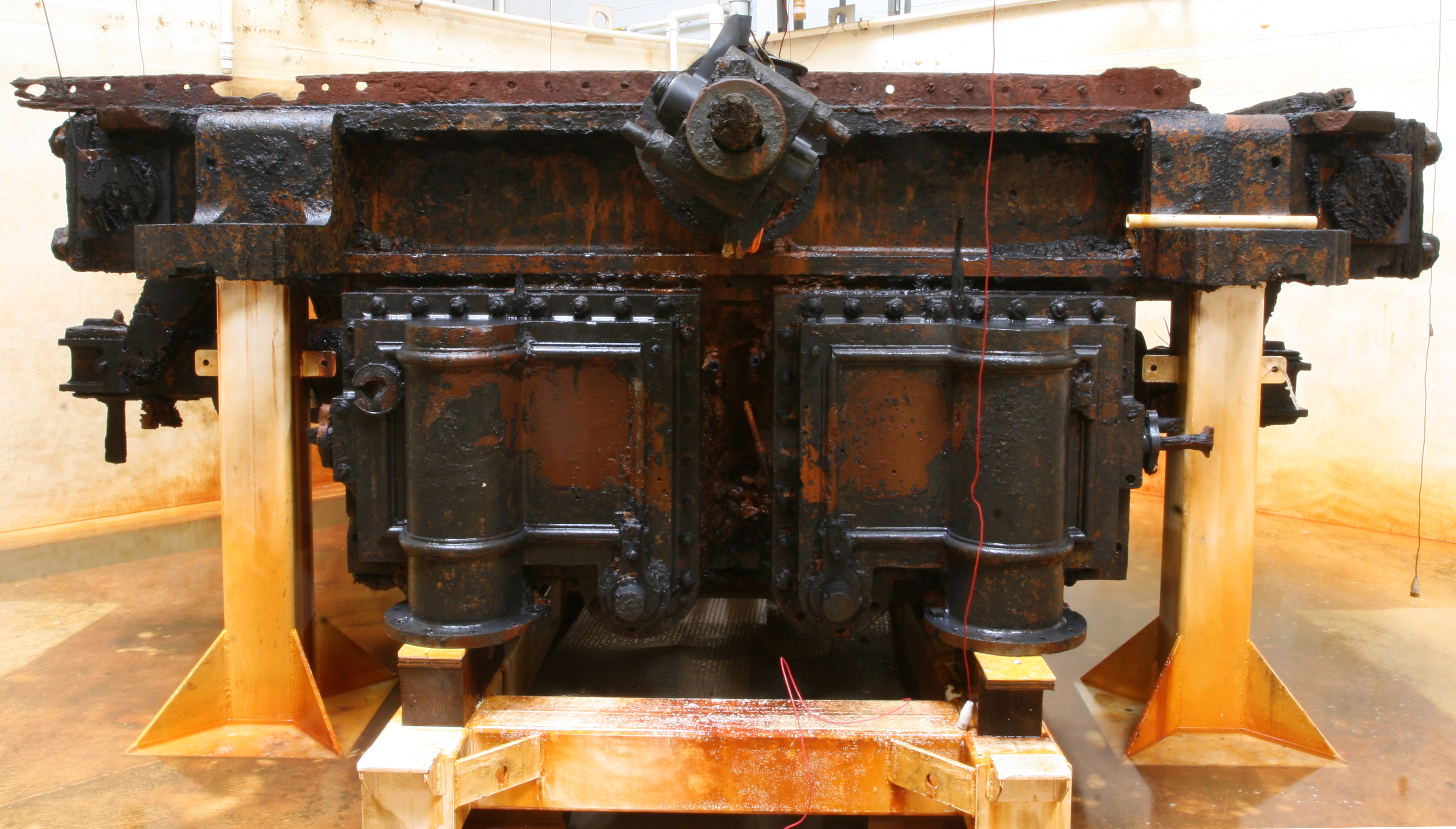

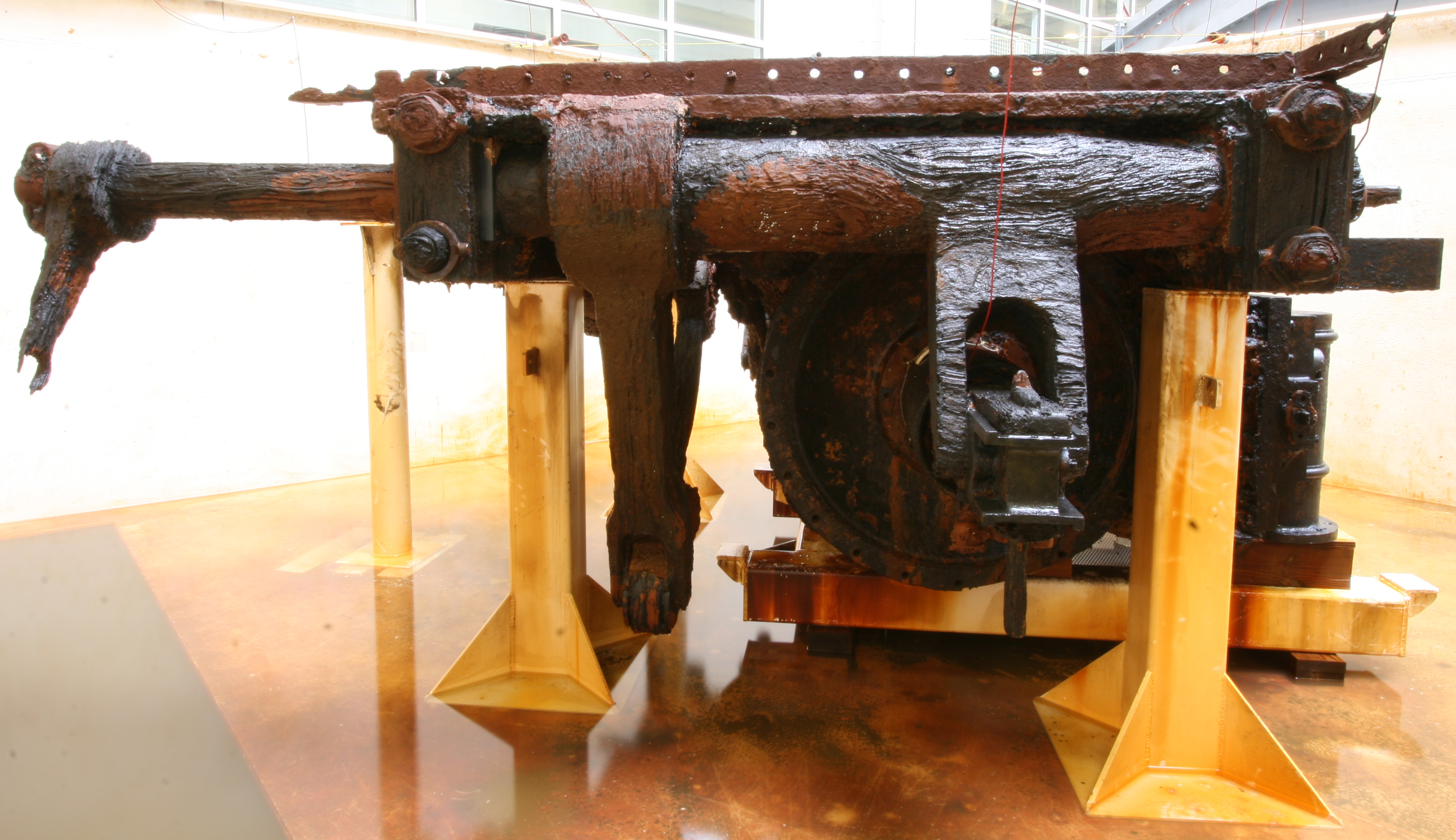

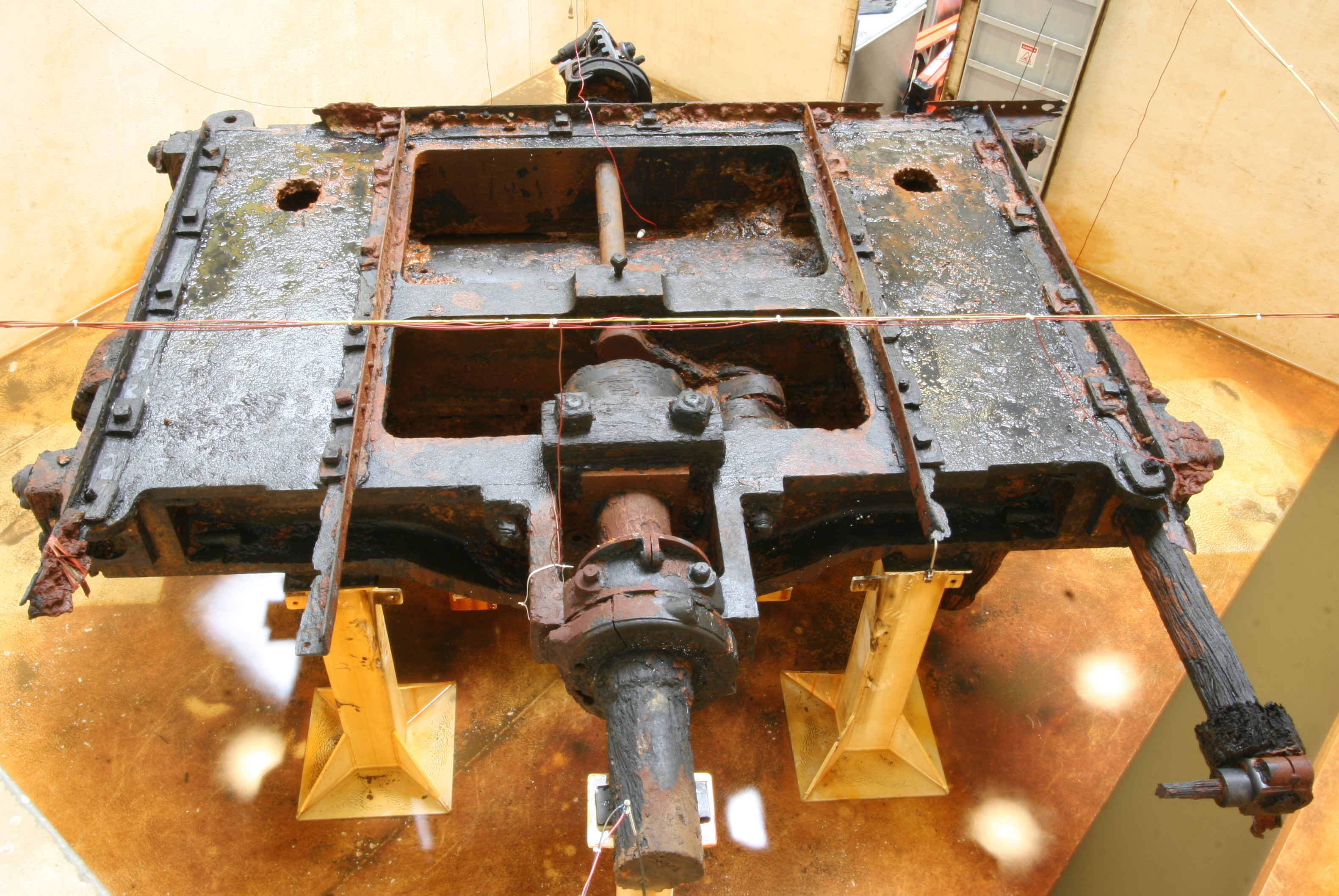

This week we’ve been very fortunate to spend some quality time with one of our oldest and dearest friends: USS Monitor‘s vibrating side lever steam engine. Much like our favorite ironclad, this salty lady is over 150 years old but keeps looking better every year.

We took the following pictures on Monday. Please remember that the engine currently sits upside down in the treatment tank.

USS Monitor‘s main steam engine treatment tank will be drained through approximately mid-day Friday, June 19. Don’t miss this rare opportunity to see the heart of the famed Union ironclad once again. She may be old, but we’re breathing new life into her at The Mariners’ Museum.