One of the things I love most about museums is that they’re a place for everyone. Especially here at The Mariners’ Museum and Park, everyone can find something that grabs their interest, whether that’s nature, sailing, military history, art, science, or all of the above!

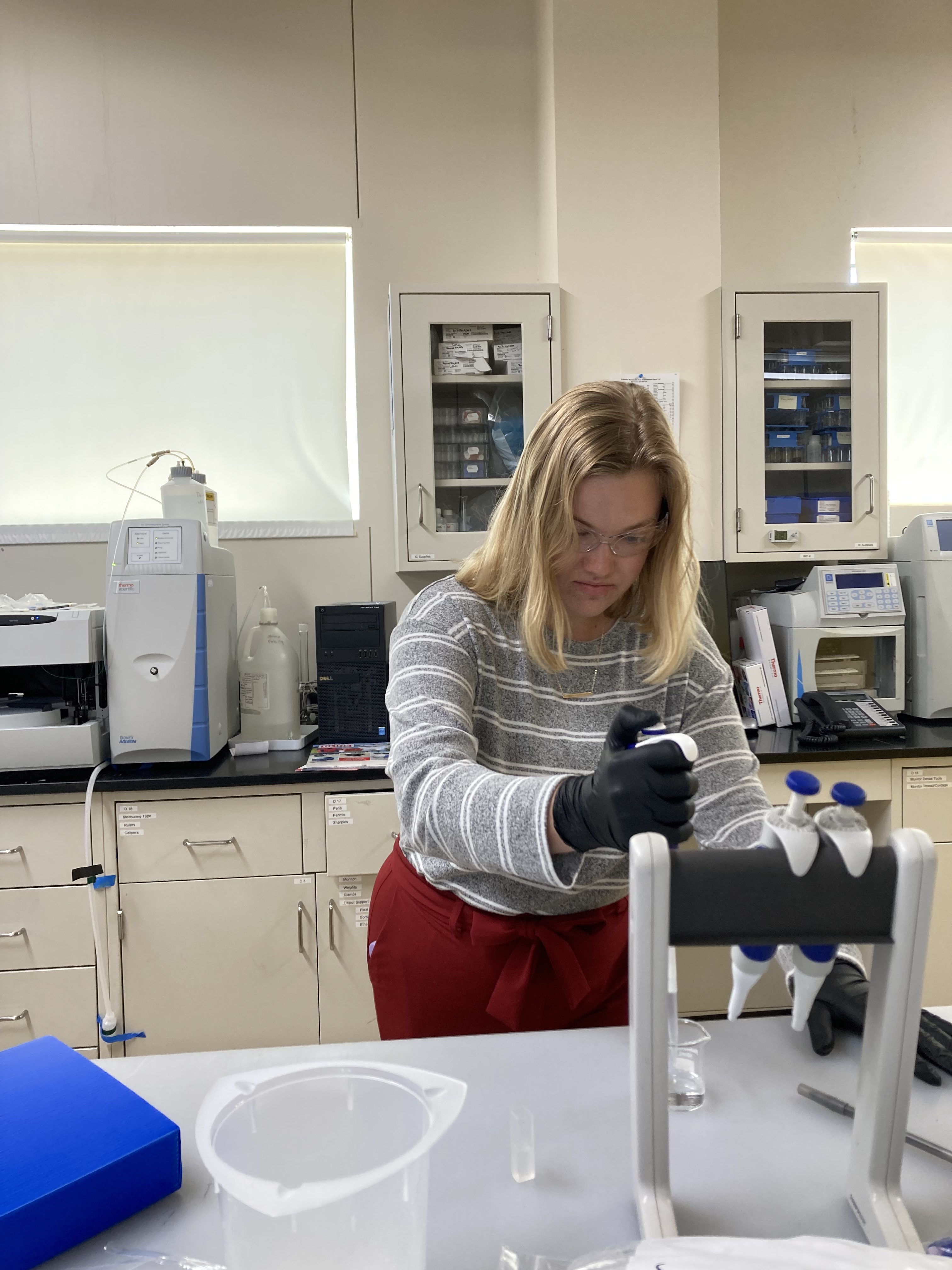

Personally, I love science and history, and I love how I get to work with both in my role as a conservation science fellow. I have an educational background in chemistry, but I’ve always enjoyed visiting museums to explore history through objects. Now, it’s my personal mission to harness the power of science to protect and preserve those objects for others to enjoy!

This summer, I’m working on a project to do just that at The Mariners’. My conservation science fellowship is generously funded by a grant from the National Park Service National Center for Preservation Technology & Training. Its mission is “to preserve cultural resources through the use of science and technology,” which is the broad aim of my work with the Mariners’ Conservation team. Within this grant project, my role is to conduct fundamental scientific research that will prevent the deterioration of waterlogged archaeological wood and support the development of a conservation treatment for that purpose.

Wrecking the Shipwrecks

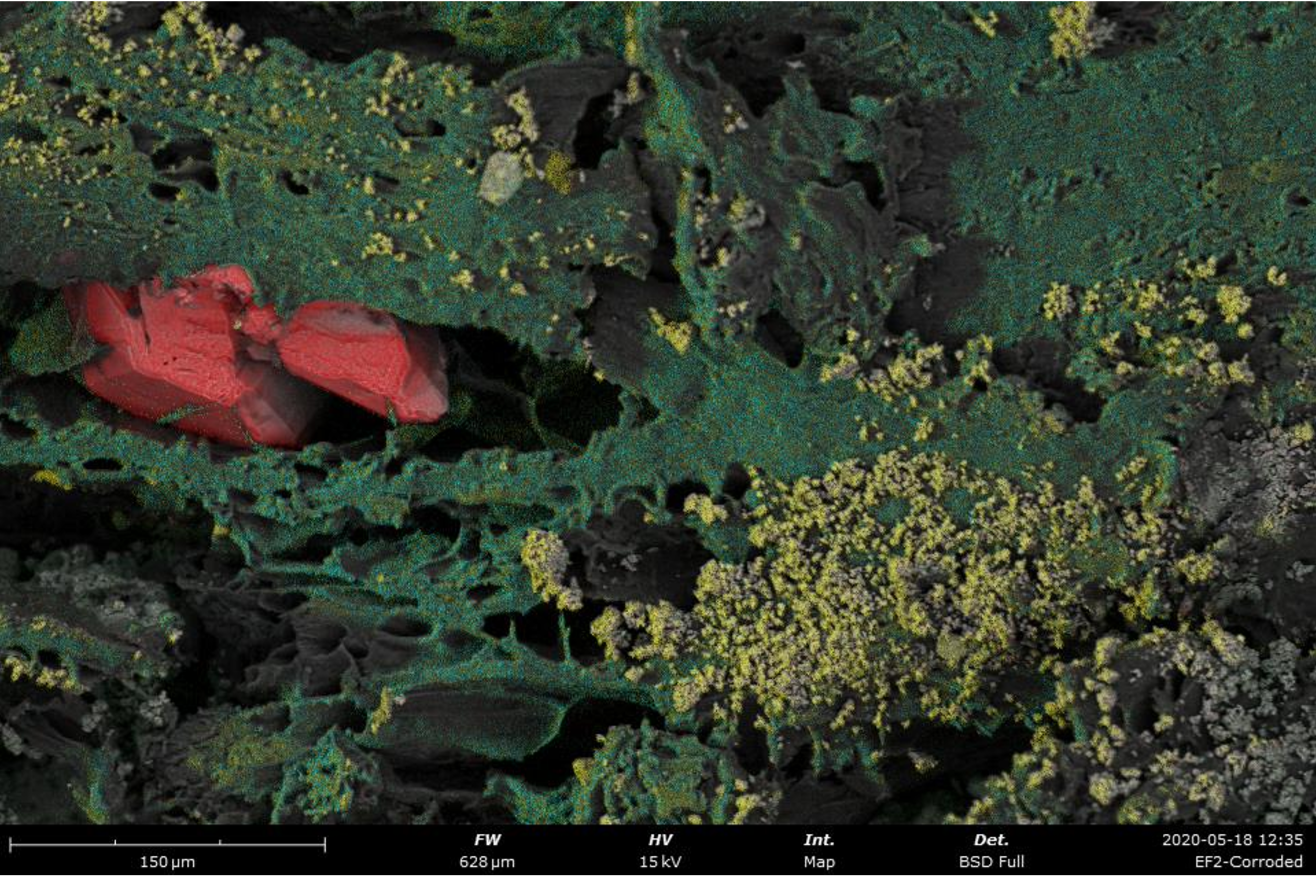

If you’re a dedicated fan of the blog, you may remember Kress Fellow Christina Altland’s work on Saving Princess Carolina. She described how yellowish white deposits have been found on waterlogged wooden artifacts. This formation of crystals on the surface of archaeological wood is a common problem in the preservation of wooden ships.

Historic ships can spend centuries in the depths of the ocean with sulfur-reducing bacteria. These tiny organisms use sulfate instead of oxygen to stay alive, so instead of producing carbon dioxide, they produce hydrogen sulfide. Over the years, the hydrogen sulfide gas accumulates inside the wood and can react to form other compounds, such as elemental sulfur and iron sulfides if there were iron parts of the ship. When sulfur-contaminated wood is excavated from the depths of the ocean and exposed to oxygen again, sulfur compounds can combine with oxygen to form crystals and acid, which degrade the wood.

An Evasive Criminal

While Christina developed a treatment to mitigate this acidification and to stabilize dried, affected artifacts, wouldn’t it be nice if this acidification and crystallization never became a problem in the first place? This summer, I’m working with Senior Conservator Elsa Sangouard and Research Scientist Molly McGath to tackle this issue. We aim to find a way to remove sulfur from wooden artifacts while they are still wet. Ideally, for future waterlogged archaeological wood, if we remove sulfur, we remove the possibility of crystals or acid forming because the prime suspect (looking at you, sulfur) is gone.

Sounds like a simple solution, right? Well it turns out, sulfur is pretty good at evading capture. It’s happy just hanging out in the wooden artifacts until it meets some oxygen and decides to become a problem.

To develop a plan of attack for the extraction of sulfur, I’m starting by reading what other people have already tried. While there isn’t a global solution to the sulfur problem yet, people have been working on it for decades, so there’s a lot of information out there about what doesn’t work.

Following Others’ Clues

You’ve probably heard that you should learn from your failures. Well, my goal is to learn from other people’s incomplete successes. Conservation teams across the globe have tried chemical and biological methods for extracting sulfur that offer some good ideas of where to start. I can also pull ideas from other fields, including the fossil fuel industry which has been working for decades to remove sulfur in emissions to prevent acid rain.

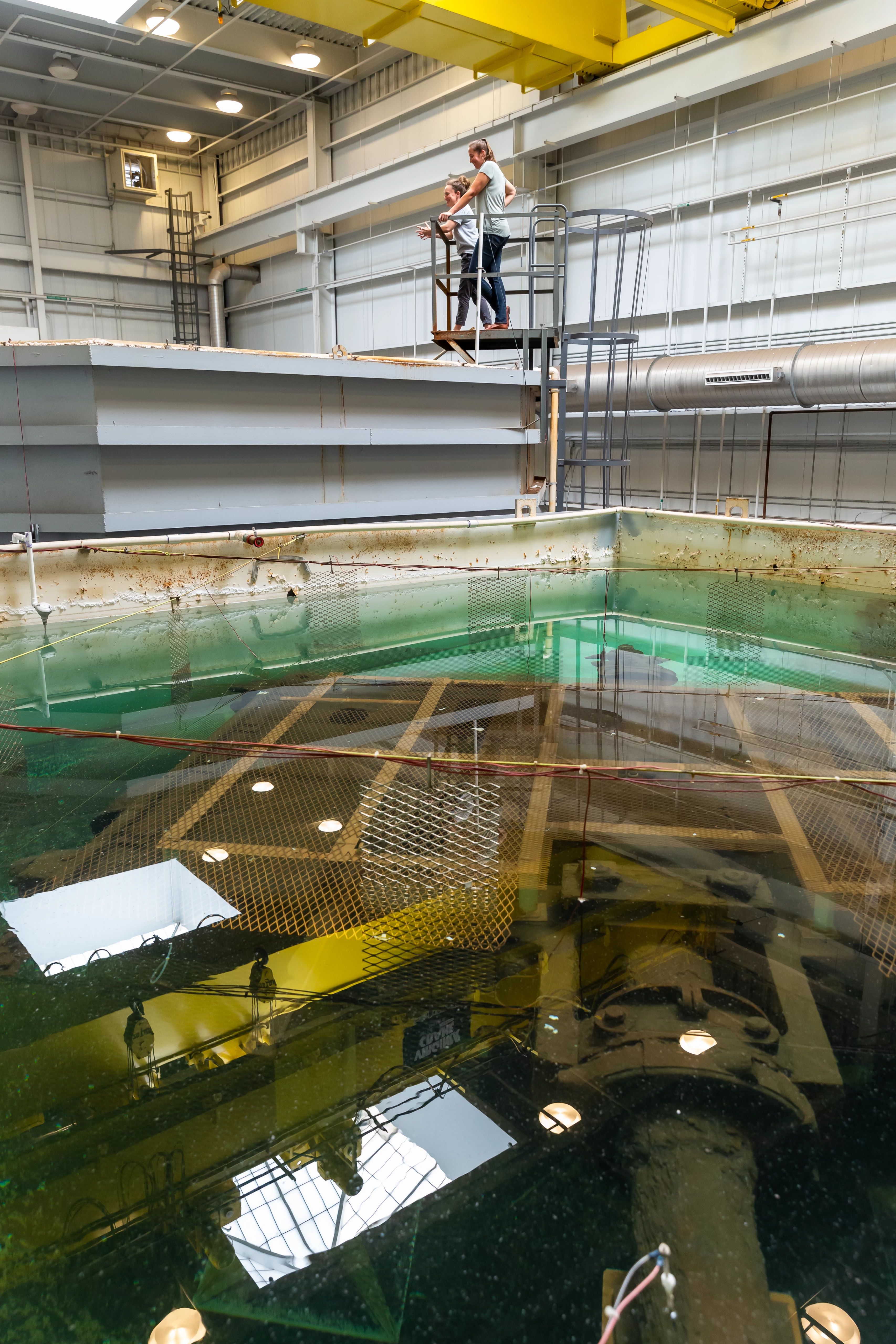

From my broad search so far, I’ve come up with a few initial experimental routes to explore. First, we are going to try dissolving sulfur in polyethylene glycol (PEG), which is already used to stabilize archaeological wood and is commonly used as a solvent in fuel desulfurization. Secondly, I’ve found some interesting studies utilizing biotechnology. Using microorganisms has been explored by researchers in the past for the preservation of stone materials. In the case of sulfur, studies have used sulfur-oxidizing bacteria to reverse the effects of the ocean’s sulfur-reducing bacteria. Finally for now, I’m also looking into electrochemical options since that’s something The Mariners’ is familiar with in the conservation of USS Monitor. In this brainstorming phase of the project, I’m casting a wide net to exhaustively investigate what is known about sulfur and what others have done to extract it so we can build on that existing knowledge.

By reading about previous research, I’m able to connect the results of different studies and adapt them to the specific problem we’re working to solve. I’ve looked at articles from chemistry, materials science, biology, physics, engineering, and conservation in order to bring in different perspectives and pull the best ideas from across disciplines. For example, many industrial processes achieve fuel desulfurization but at high temperatures and pressures, which would not be suitable for archaeological wood. However, I can build off those ideas and turn to conservation sources for information on how to prioritize object safety. Then, I can look up chemistry sources to gather details for testing these ideas in the lab. I can grab little ideas from a variety of previous research studies to come up with innovative solutions.

Taking It to the Lab

Right now, I’ve sourced information on the problem and brainstormed new experiments, so I’m ready to head into the Clean Lab and test my ideas on paper. No, actually, literal paper! Since paper is made from wood, it makes a great test sample. We’re going to add small amounts of known sulfur compounds to the paper and monitor how they move through the paper when exposed to PEG. This can tell us how soluble different sulfur compounds are in PEG and how well PEG might work for sulfur extraction in archaeological wood. This fundamental research will help us learn more about the chemistry involved in the extraction process so we can continue to design new experiments and come closer to an extraction solution.

Stopping Sulfur in its Tracks

At this point, we still have a lot of work to do before any treatment could be implemented on artifacts. However, conducting background research on sulfur chemistry and controlled experiments on paper are necessary steps toward developing a safe preventive treatment for waterlogged archaeological wood.

Sulfur contamination is likely to occur in organic materials from nearly all marine excavation sites. Therefore, finding a way to extract sulfur before it causes acidification and damage to these objects would be huge progress for maritime museums across the globe.

Hopefully at the end of my fellowship, the team will have a clearer path toward solving the sulfur problem once and for all so that wooden artifacts will be stable for museum visitors around the world to learn from and enjoy. I’ll keep you posted on my experiments, and I invite you to come up to the Clean Lab and see the work in progress!

References:

(1) Meng, X.; Zhou, P.; Li, L.; Liu, L.; Guo, M.; Sun, T. A Study of the Desulfurization Selectivity of a Reductive and Extractive Desulfurization Process with Sodium Borohydride in Polyethylene Glycol. Sci. Rep. 2020, 10 (1), 10450. https://doi.org/10.1038/s41598-020-67235-8.

(2) Monachon, M.; Albelda-Berenguer, M.; Lombardo, T.; Cornet, E.; Moll-Dau, F.; Schramm, J.; Schmidt-Ott, K.; Joseph, E. Evaluation of an Alternative Biotreatment for the Extraction of Harmful Iron and Sulfur Species from Waterlogged Wood. Eur. Phys. J. Plus 2021, 136 (9), 937. https://doi.org/10.1140/epjp/s13360-021-01908-9.

(3) Albelda Berenguer, M.; Monachon, M.; Jacquet, C.; Junier, P.; Rémazeilles, C.; Schofield, E. J.; Joseph, E. Biological Oxidation of Sulfur Compounds in Artificially Degraded Wood. Int. Biodeter. Biodegr. 2019, 141, 62–70. https://doi.org/10.1016/j.ibiod.2018.06.009.

(4) Tran, K.; Bertout, N.; Dalard, F.; Magnin, J.-P. Trials on Chemical and Microbiological Processes for the Oxidation of Sulphur Compounds in Archaeological Wood. In Proceedings of 9th ICOM Group on Wet Organic Archaeological Materials, Copenhagen 2004; Hoffman, P., Spriggs, J. A., Grant, T., Cook, C., Recht, A., Eds.; ICOM-CC: Copenhagen, 2005; pp 227–242.