The Mariners’ is the proud caretaker of more than 200 tons of artifacts recovered from the wreck of USS Monitor, including its revolving gun turret, Dahlgren guns, steam engine, and more. In partnership with NOAA’s Monitor National Marine Sanctuary, we are honored to conserve, preserve, and share Monitor‘s incredible story to audiences worldwide.

The USS Monitor Center houses the award-winning exhibit Ironclad Revolution as well as the largest and most advanced conservation lab of any maritime museum in the world, The Batten Conservation Complex.

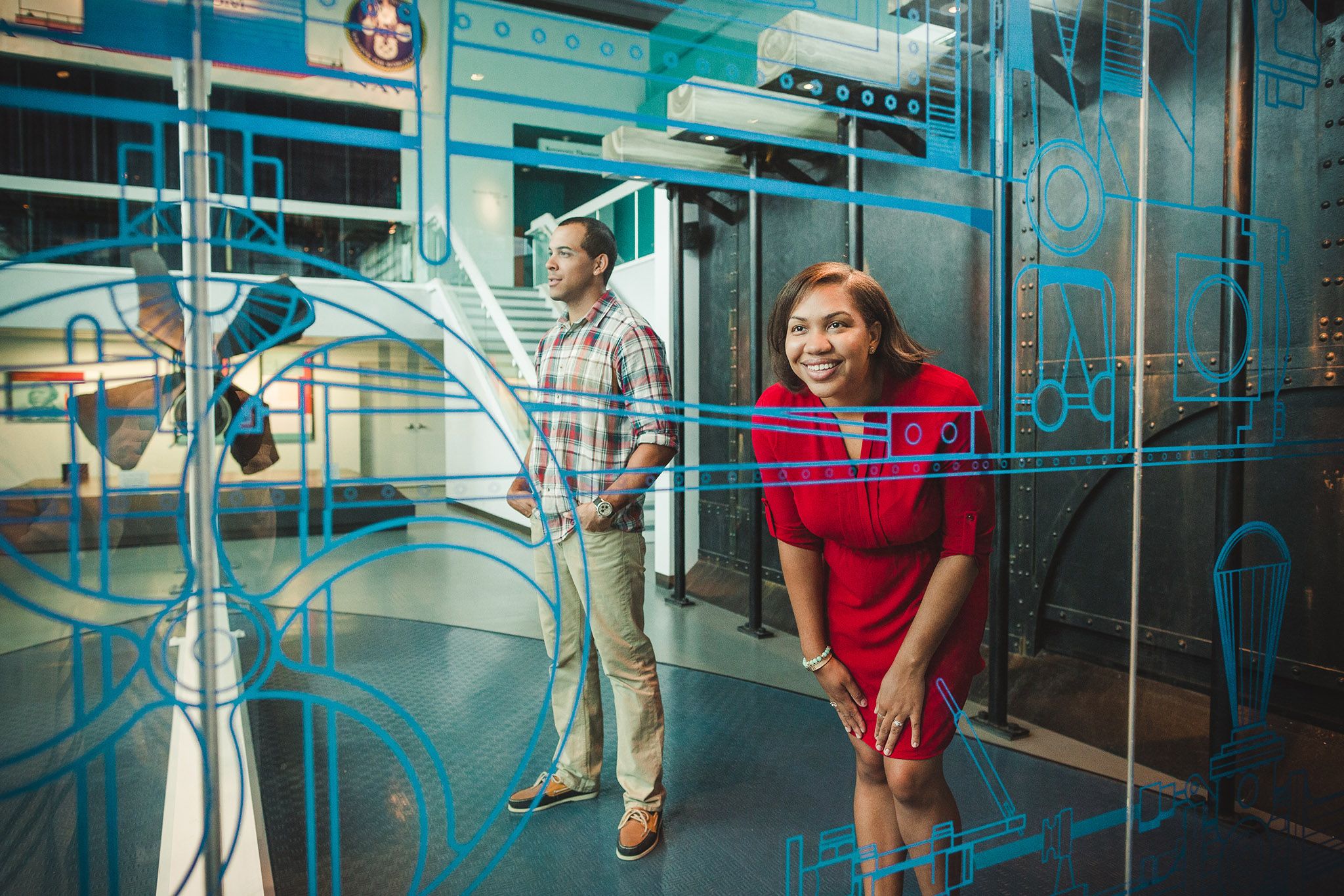

Ironclad Revolution invites you to experience the story of USS Monitor, CSS Virginia, and the historic 1862, Battle of Hampton Roads through a melding of artifacts, original documents, paintings, personal accounts, and interactives that will pique all five senses. Immerse yourself in the tales of the individuals who lived through and lost their lives in this pivotal period of American history.

What you’ll experience

- Be a part of the action in the high-definition Battle Theater. This 15-minute film* is family-friendly and gives a play-by-play of the Battle of Hampton Roads.*

- Walk the deck of the full-scale Monitor replica. See if you can find and ring the ship’s bell.

- From the Batten Conservation Complex observation platform get a bird’s eye view of Monitor’s turret, Dahlgren guns, and steam engine undergoing conservation treatment.

- Try your hand at designing your own ironclad ship. Will it sink or be a record-setting warship?

- Go back in time as you explore the building of CSS Virginia from the salvaged Merrimac at Gosport Navy Yard.

- Venture upstairs to the Batten Conservation Complex Clean Lab to see our conservators at work!

*Note: Please be advised that this presentation has unexpected loud sounds and flashing lights that may be disorienting for some visitors.

The Batten

Conservation Complex

The Batten Conservation Complex, a 15,000 square-foot state-of-the-art facility, is dedicated to the conservation and long-term care of The Mariners’ world-class Collection.

The laboratory complex consists of three distinct work areas: an industrial-scale Wet Lab, a Clean Lab, and an Archaeological Collection Storage and Research area. While the complex is the home of the USS Monitor Collection and the world’s largest marine archaeological metals conservation project, The Mariners’ Conservation team also actively conserves and stabilizes various objects from the Museum’s diverse Collection.