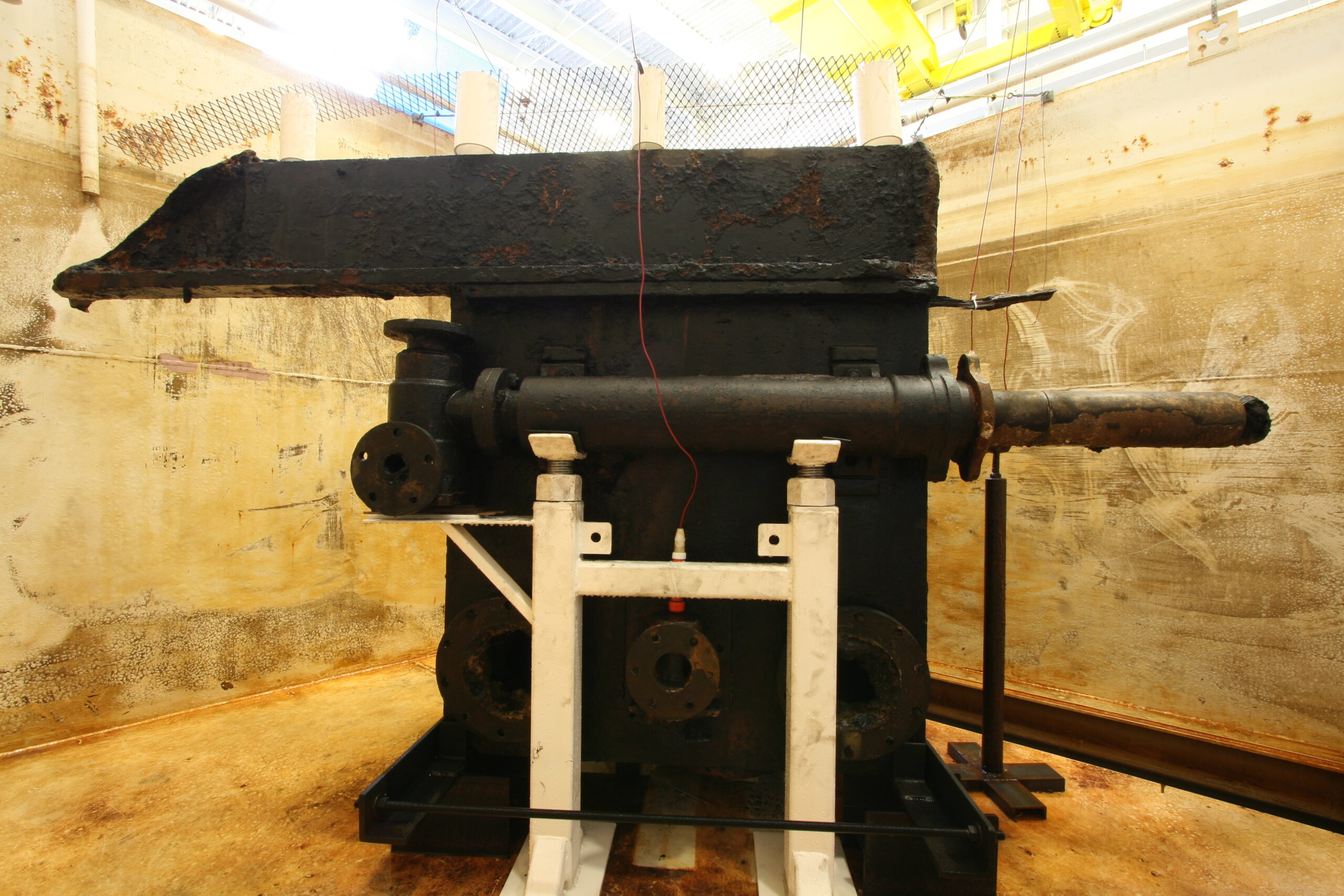

Following a break in the action that included Will going off to the American Institute for Conservation (AIC) annual conference to give a great presentation on the Worthington Pump casting project, we were back in the condenser tank for one final week of excitement. Will finished up the injection pump supports and they were installed after some minor de-concretion work. Our shiny new anode rig went into place without any trouble at all. We spent half a day up and down ladders, placing new reference electrodes and ensuring that all of the wiring was as it should be. The tank was also thoroughly scrubbed.

Then came the morning we had been waiting for. Everything was in place inside the tank, it was time to add the new sodium hydroxide solution. This action proved once again that the scale of the Monitor project is bit different than anything I have previously encountered, as we added thirteen 50lbs bags of sodium hydroxide pellets to the purified water pumped into the condenser tank. Yes, 650lbs is a lot and a greater quantity of chemical than I have ever previously handled at one time. The filling of the tank marked the end of our work on the condenser for now, and caused a great feeling of satisfaction within the lab.

Just a reminder that our Monitor origami challenge is still ongoing. You have until the end of June to submit your origami Monitor. All of the details can be found in the previous blog post. Located here. Be sure to check back to our blog soon as we have got a story for you. I’m not going to give away any of the details now, but I will say that it involves a painting, a ship (not the Monitor), our x-ray machine and a mystery.

Aft side of the condenser with injection pump support and reference electrode in place.