Some of you might remember my post of September 22 where I discussed the discovery that one of the swivel guns we had pulled for the Gallery Crawl appeared to be loaded. Well, I can now happily report that it was not loaded but it did have SOMETHING jammed inside of it (and no, it wasn’t a beer can, although I will admit to having one of those stuck inside a 4-pound mid-18th century British cannon). We did have a brief scare in early October when we sent a sample of material from the touchhole to William & Mary and it tested positive for the elements of gun powder. Thankfully we now know that it was just the remnants of gun powder from the touchhole and not a fully loaded cannon—which I guess I should have expected.

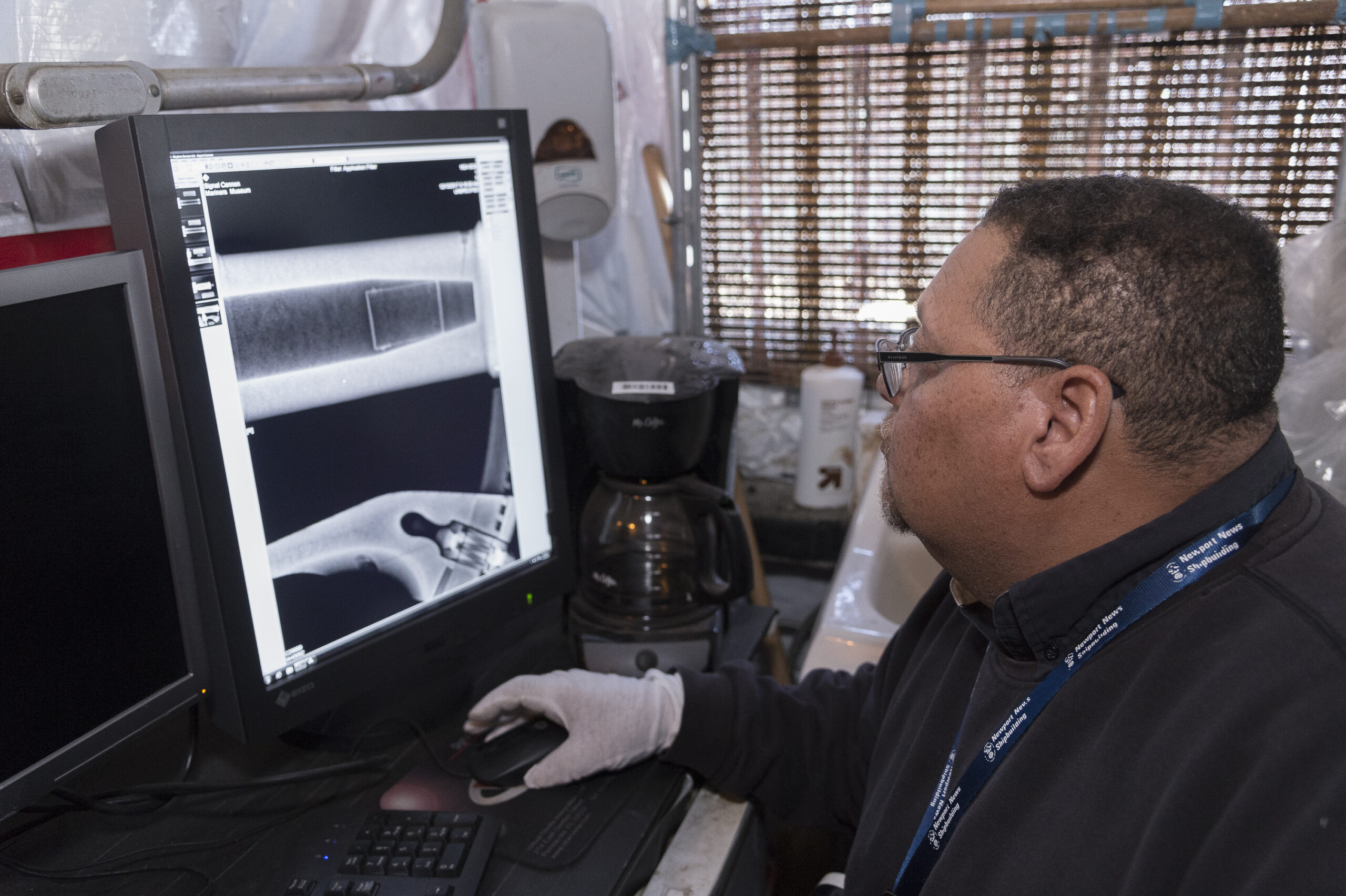

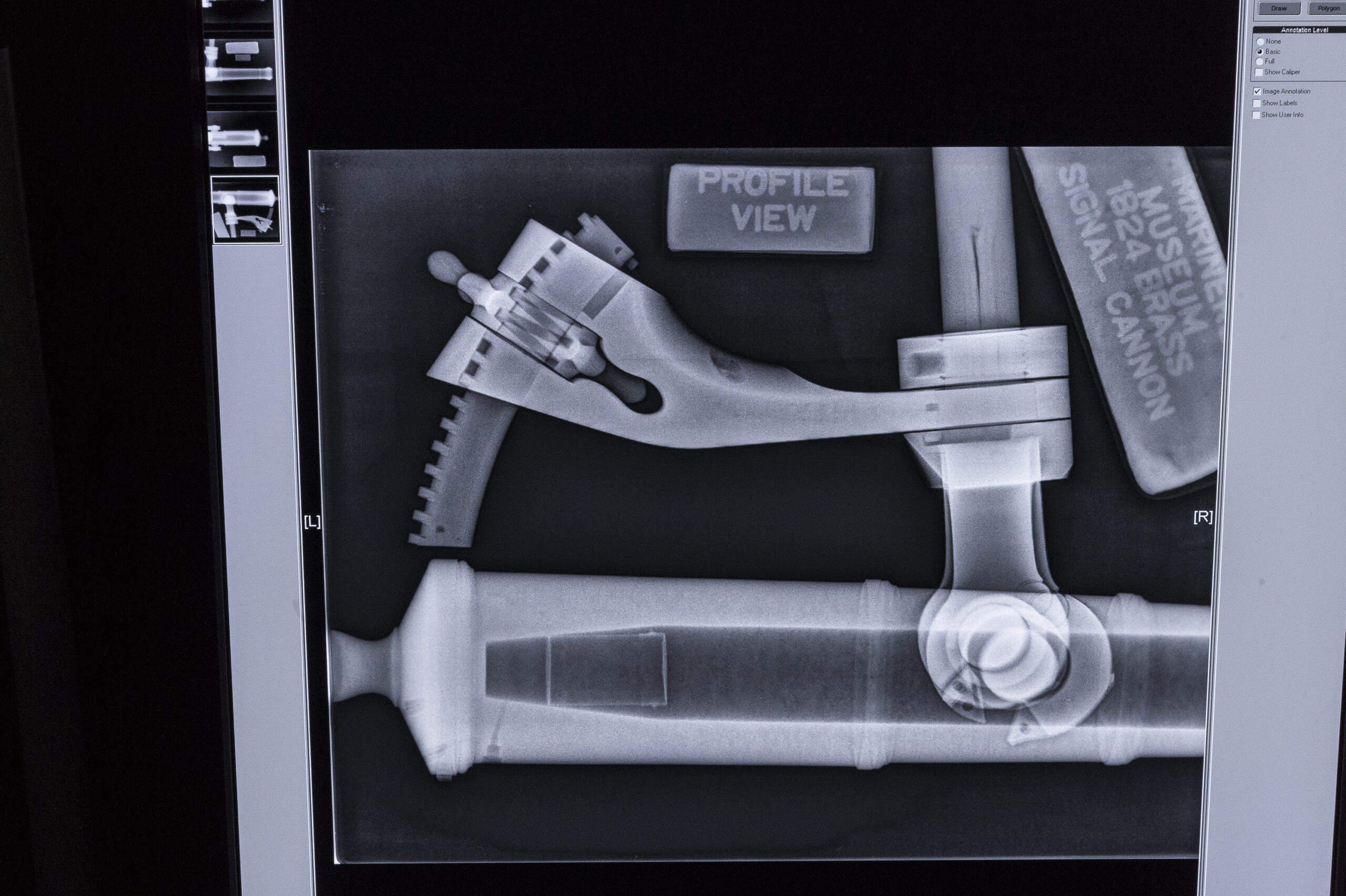

Shortly after the Gallery Crawl we contacted Newport News Shipbuilding and they graciously agreed to help us by x-raying the cannon (you might remember that ours wasn’t strong enough to see through the barrel while NNSBD’s machine can penetrate steel up to 20 inches thick). This isn’t the first time NNSBD has pitched in to help the Museum. Over the last 20 years or so they have periodically used their linear accelerator, high energy X-ray machine (Linitron) to x-ray objects recovered from the USS Monitor.

Last week JJ Bosco and Mike Bryant from NNSBD’s NDT Engineering and Inspection department came over and picked up the cannon and carried it to the shipyard. The following day, their team performed computed radiography (CR) on the cannon and a couple of other items we needed help with.

Besides JJ, who coordinated everything, the team included Dean Lavinder (who operated the GE CR Scanner); Randall Hall (who operated the GE Vision CR System); Mike Bryant (who coordinated the foundry operations); Kevin Walker (who set up the CR shots and ran the Foundry Linitron); Donna Blankenship (she is the Chief Inspection Supervisor and helped get the objects back to the museum); and NNSBD photographer John Whalen who documented the whole process for us.

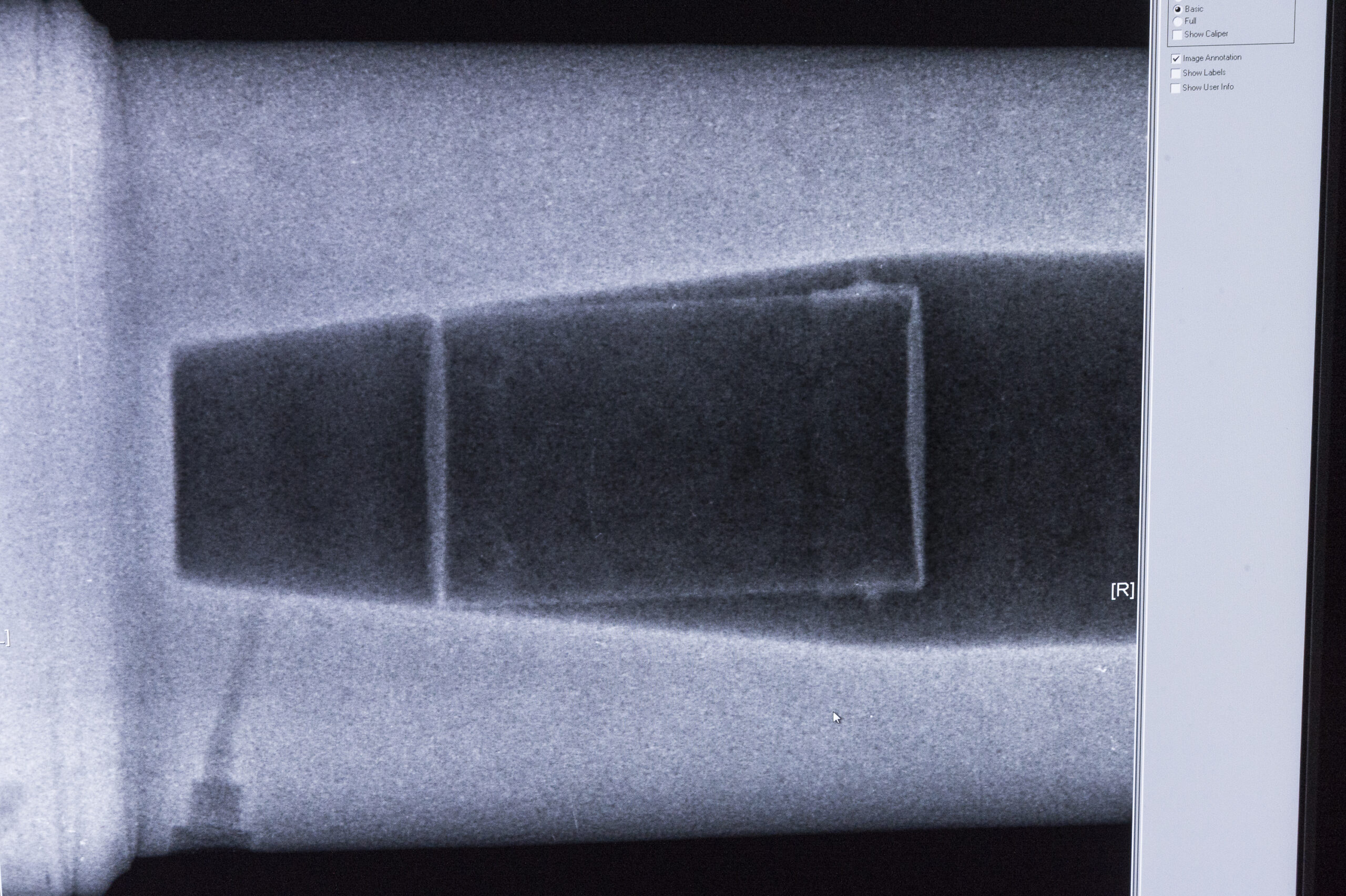

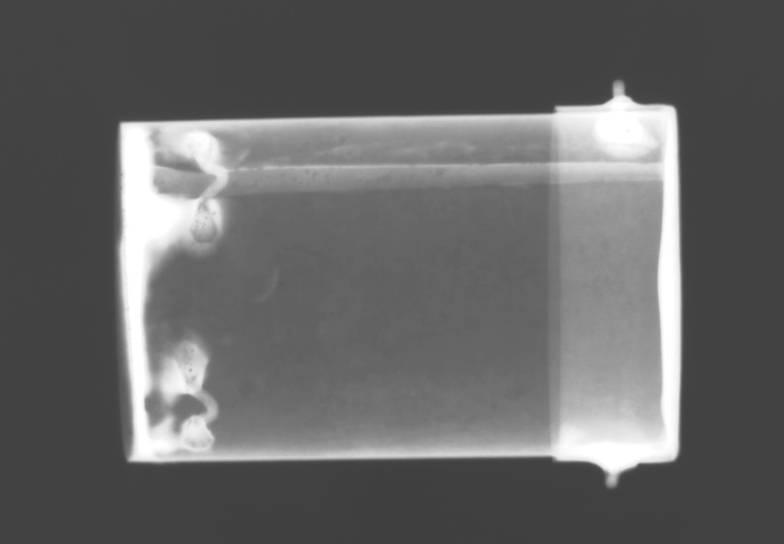

We got the x-rays back last Thursday and the images were so crisp and clear that even the finest details were visible on the CR system’s high resolution computer monitor. The images clearly showed the cannon wasn’t loaded and gave us a much better idea of the shape of the object stuck inside the barrel.

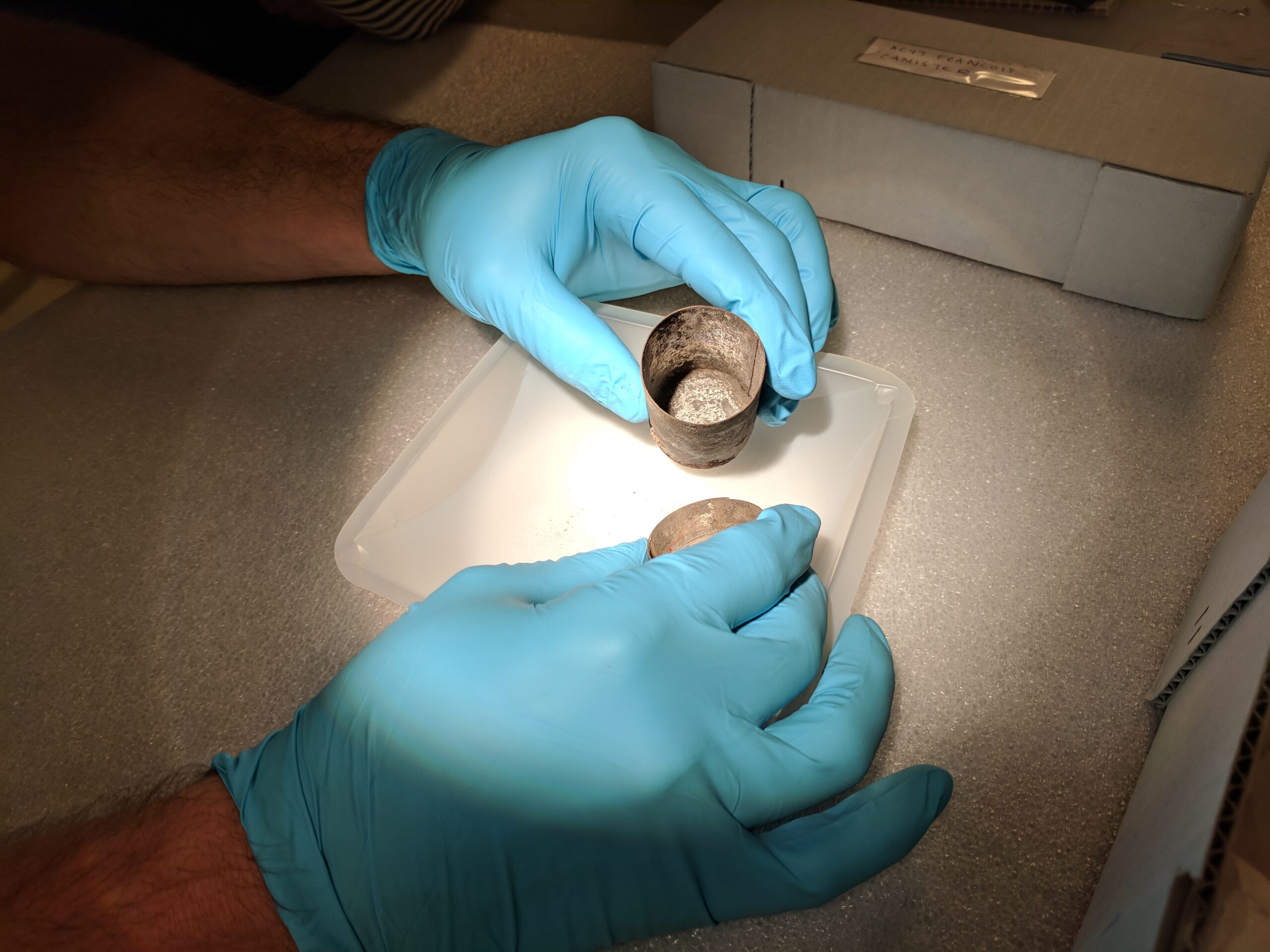

Curator Marc Nucup and I were determined to try and save the obstruction in case it might be something historic. It appeared to be paper thin so prying it out wasn’t an option. After talking to Chief Conservator Will Hoffman we decided to try and clear the obstruction with compressed air, which was the option that presented minimal risk to both the item and the cannon. I recruited Chris Voll in our exhibit production shop to help but beforehand I wrapped the end of the barrel with a packing blanket to catch the obstruction as it launched out of the barrel (I didn’t want it to get lost or destroyed). Chris armed his air compressor with a rubber tip and forced the tiniest bit of air through the touchhole and almost instantaneously the obstruction launched out of the barrel with the coolest “ffwwomp” sound. (Chris and I just looked at each other and at the same time said “is that it?” I don’t think either of us expected it to be so easy!)

And guess what? We STILL aren’t completely sure what it is!

The piece is a small canister-shaped object 2-1/8” high by 1-3/8” in diameter with a soldered seam up one side. It has a bottom and a little cap that also has a soldered seam. There are two little loop straps soldered to the cap and two more at the base of the canister. It looks like the metal was tinned at some point. It also had a small piece of string left over in one of the loop straps. Right now, the general consensus is that it is a small container for a pre-measured charge–kind of like an apostle on a bandolier. Marc doesn’t think the container would hold enough gunpowder to fire a cannon ball, but it would definitely hold enough to make a signal.

Wednesday we x-rayed the canister and determined it’s empty so the next step is to try and open it. At that point, I guess if there is gunpowder residue on the inside then our question about what the piece is will be provided!

UPDATE!

We managed to get the canister opened last Friday. It was empty but we plan on testing the residue inside to see if it might have contained gunpowder. Interestingly, the inside of the container is tinned.