Last month, I began writing about the case of the Daniel J. Morrell, a Great Lakes bulk carrier built in 1906 that went down in a gale in November of 1966. I thought I would tell the story of how the ship split in two, and how all hands perished save 1 man. I thought, “How very like the story of that film, The Finest Hours, that told the story of Bernie Webber and his crew of Coasties who saved 32 sailors from the wreck of the T2 tanker Pendleton. In both cases, the bow section split off and sank, as the stern section just sailed on.” The Michael Tougias & Casey Sherman book of the same name, by the way, served as the basis for the movie.

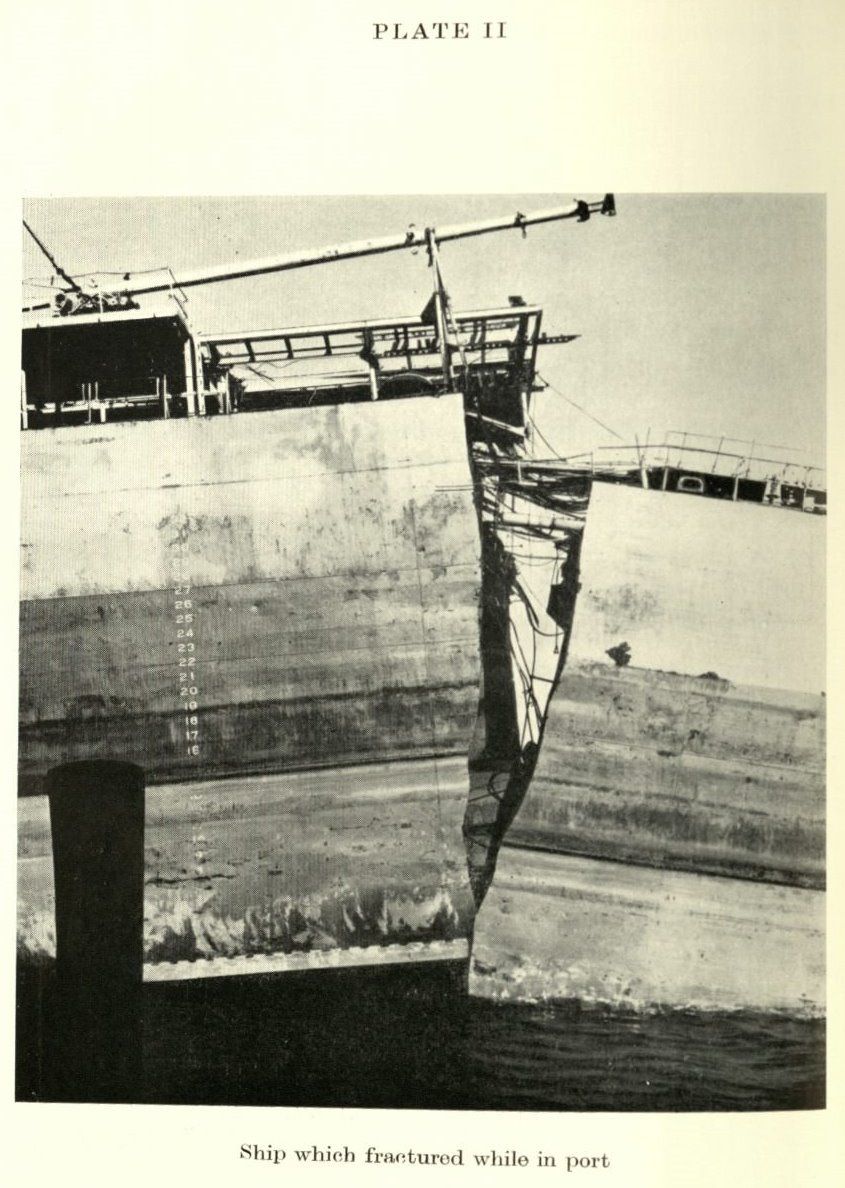

Then I thought about other ships that split. The T2 tanker Fort Mercer, that went down in the same storm as Pendleton. The Carl D. Bradley, another Laker. The T2 tanker Schenectady, just sitting at dock when it suddenly hogged and split. Historians have documented 19 Liberty ships as having split in 2 without warning. There were just too many ships, too many lives lost! What was happening to these vessels?

The cases

Let’s take a look at the specifics of some of these vessels, to see what happened to them. First, the Morrell.

Daniel J. Morrell

The West Bay City Ship Building Company in Michigan built the riveted steel-hulled Daniel J. Morrell, a non-self unloading freighter working on the Great Lakes, in 1906. At just over 584 feet long, she was brushing up against length limits for the Lakes. Because she lacked a self-unloading mechanism, big buckets were constantly banging in and out of her cargo holds. She had water-tight bulkheads forward and aft of her three holds, but bulkheads between holds were not water-tight. In those days, even for ships this long, there was no rule book on how to load and ballast her. Lake masters knew by experience how to do it. If it wasn’t done just right the twisting forces on her hull would have been enormous.

Her hatch covers were the good sliding kind, and the hatches were square. She had AM and FM radio stations, but no emergency radio, and her life boats were open to the weather. There had been leaks in her side ballast tanks, and a dry dock company in Toledo, Ohio, repaired her shell plating by butt-end welding new plates to the riveted plates around midships.

The storm that sank her was a true “witch of November”. On the 28th of that month, 1966, the Chicago weather bureau issued a Gale Warning for Lake Huron, blowing at maximum northerly at 41 to 47 knots, with rain or snow for a 24 hour period. Conferring with other captains, the master of the Morrell, who was in ballast and unloaded, decided to continue his voyage up-bound to Taconite, MN. What Captain Crawley found, around midnight of the 29th, were tremendous winds from the north at 65 mph, 25-foot seas. The crests were coming every 250 or 300 feet. He was blown off-course and nearly broached at least once. (VK1255.D33 U5, SS Daniel J. Morrell Sinking with loss of life, U.S. Coast Guard Marine Board of Investigation report)

The lone survivor

The only man left alive the next morning reported what happened next. The ship split in two amid-ships, the stern section still under power and bumping the port side of the forward section. The bow eventually separated and sank. The lone survivor, Dennis Hale, reported that the stern section continued sailing on. With air temperatures in the 30s and being almost naked, it is miraculous the man lived.

Divers found the stern wreckage in January of that winter. They did not find the bow section until twenty years later, 4 miles south of the stern.

Carl D. Bradley

The Bradley‘s story is remarkably similar in terms of the storm. That Lake Michigan gale was a sou’wester, with winds at about 65 mph. on Nov. 18, 1958. Seas were also running high, about 20 feet, but wave crests were much shorter, coming every 50 – 75 feet.

Another very, very long ship!

Now the Bradley was a much bigger boat, the largest of the Lakers when American Shipbuilding in Lorain, Ohio, built her in 1927, coming in at 623 feet long. She was a self-unloader, with 2 watertight bulkheads like Daniel J. Morrell fore and aft of the 5 cargo holds. She had a tunnel through which the conveyer belt of the unloader passed with a clear shot through all the vessel’s holds. It too had a riveted steel hull.

Like the Morrell, the Carl D. Bradley was riding in ballast on that day with no cargo, crossing the northern lake from the Wisconsin side to the Michigan side. She therefore took the seas on her starboard quarter, but rode so comfortably the crew never even put up sideboards on the mess table. Her master also put her in ballast according to experience, rather than a loading manual. Also like the Morrell, she had had a few problems with structure, including hairline cracks on the bottom, and had rubbed bottom a couple of times in the recent past. More seriously, Carl D. Bradley had collided with the motorship White Rose in April 1956, which resulted in transverse cracks midships. Yard workers repaired them by cutting out the fractured plates, and replacing them with plates that they butt-welded flush with the hull and riveted at the seams.

The two survivors

When Carl D. Bradley split in two, there were 2 survivors out of 35, Frank Mays and Elmer Fleming. These men reported hearing a thud, and looked out from the bow to see the stern section sagging. Both sections sank in minutes on an even keel. The master ordered an “Abandon Ship” alarm and the broadcasting of “Mayday.” Crewmen life swung out lifeboats, but weather conditions impeded their launching. Several stations heard the “Mayday” call and the Coast Guard and other ships responded immediately. A life raft containing 4 survivors constantly overturned in the heavy seas, and 2 of the 4 perished that way before the CG cutter Sundew rescued them. Frank Mays, the last survivor of the Carl D. Bradley, died just 3 weeks ago, on January 8, 2021.

The T2 Tankers

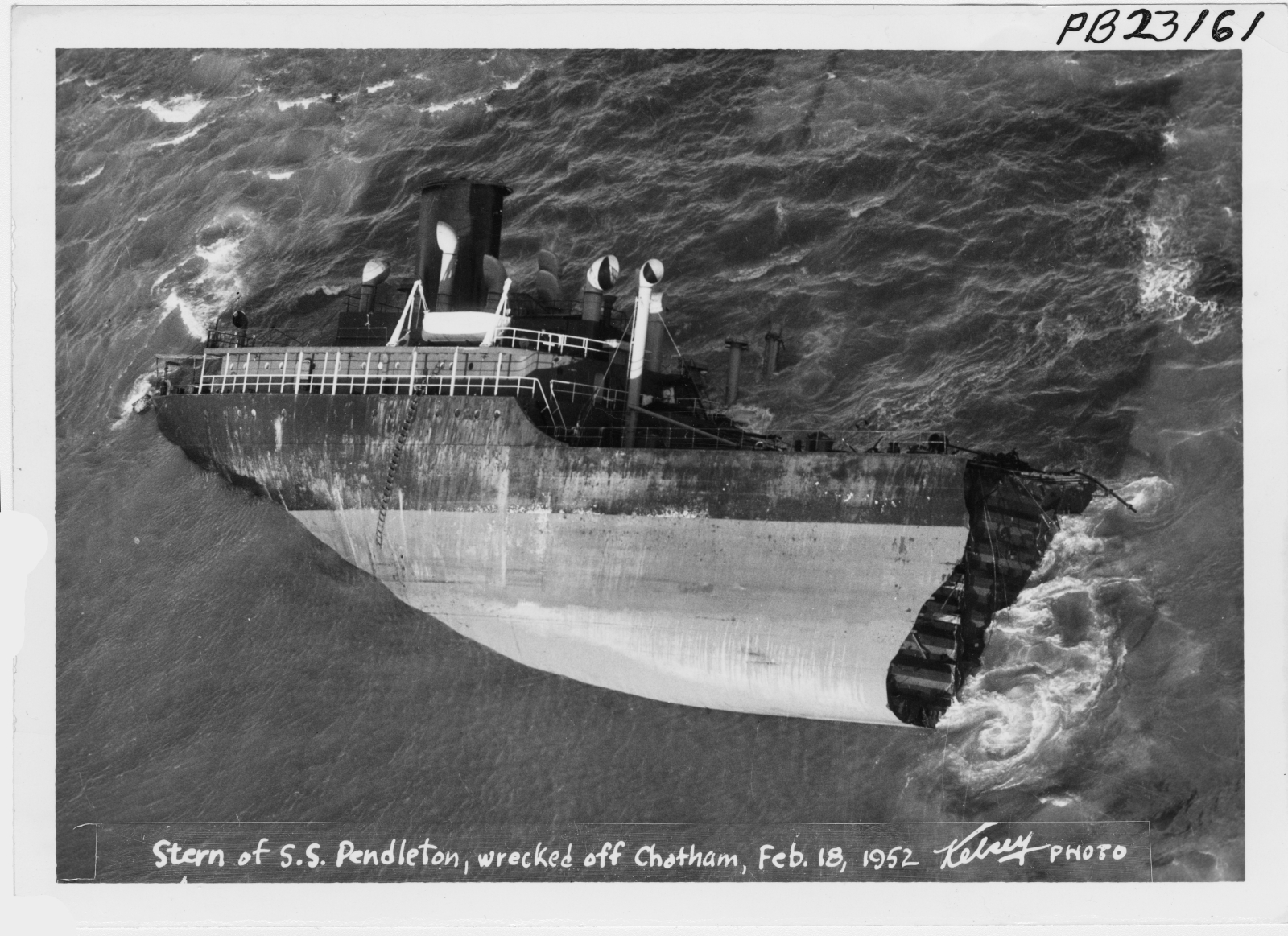

If you have seen the movie or read the book I referred to at the beginning of the post, The Finest Hours, you will have a fairly good idea of the essentials of the wrecks of both Pendleton and Fort Mercer in that blizzard of February 1952 off Cape Cod. American yards built these ships in haste during World War II to carry diesel fuel, fuel oil and crude. In that 1952 blizzard, seas were twice what they were on the Great Lakes, working up to 70 feet. Winds were 50-60 mph at the time of the Pendleton rescue, and the water temperature was around 41F. See the Coast Guard reports on these disasters here and here.

The ships, all-welded construction, both carried loads of kerosene and fuel oil in their mid-section tanks. The foremost and aftermost tanks were empty. In the seas they were facing, both tankers found themselves on occasion perched on high waves fore and aft, leaving immense stress and a tendency to sag at midships.

Pendleton had suffered a grounding earlier in the year, and Fort Mercer had had some structural work done to cut its bilge keel. Both had the 4 required crack arrestors in place, mandated since the dramatic hogging and splitting of the new T-2 Schenectady just sitting at its dock in 1943. Everyone involved with these Liberty cargo and tanker ships knew the problem was serious, from crews who manned them to shipyards who built them to regulators and oversight agencies. Something was wrong with the welding. The steel plates, instead of flexing and bending, just snapped. Four men died on Fort Mercer, and nine perished on Pendleton.

Why did this happen?

Metallurgists call this problem brittle fracture. At the heart of brittle fracture is the steel itself. What follows is a huge over-simplification of the matter, so please forgive me if I omit important details here.

A primer on steel

Steel is mostly iron, of course, to which you can add carbon to make it really hard. Iron is quite ductile — it bends, its crystals just slip nicely past each other under stress. You add carbon, and it hardens the crystalline structure, gives it tensile strength. Too much carbon and you end up with pig iron or even cast iron. So you add just some carbon to make steel. Then you modify it with a host of other elements, to give it characteristics that you want.

There are, as always, tradeoffs. Sulphur, for example, tends to make steel ship hull plates really brittle and prone to fracture. It also makes the steel hard to weld. But it makes for a steel that is better for machining. Add some more manganese to your steel, and the sulphur problem goes away. Phosphorus will cause hardened steel to get more brittle, quite undesirable. But in low-alloy high-strength steel, it improves both strength and corrosion resistance. (See a nice explanation of how various elements affect steel here).

The heart of the matter

Sulphur and phosphorus are impurities that were present in too great a measure in the steels of ships that split in two. It was hard to weld them, and the welding materials and processes weren’t nearly what they are these days on the carriers built at Newport News Shipbuilding. Welding those plates also created transition zones in the plate, areas that the welding heat deformed. That deformation made them less elastic and more brittle. The welds themselves broke because the metal next to them failed. That metal got hot and changed from elastic to plastic.

Add to these material problems a notch or a little cut or a small crack in the steel from, say, a repair or a grounding, or even a square-cornered hatch, and a ship is in trouble. Then make it a really cold day in cold water. Add the flexing, twisting, hogging, or sagging of steaming into the teeth of a gale, or just loading and offloading cargo over the years. Now you are headed for disaster.

How do you fix it?

Riveting those crack arrestors to the hull and deck helped, but did not fix the materials problems with either the T-2 tankers or the old Lakers. Adding 4 more to the initial 4 required in the tankers after the Pendleton and Fort Mercer split was one measure to extend the life of these vessels. The stern section of the Fort Mercer stayed afloat and two big tugs (M. Moran and Foundation Josephine) actually towed it stern-first under steam into Newport, Rhode Island! The shipbuilders in New York put another bow section on it, rechristened it as the San Jacinto. Twelve years later the ship split in two again!

Since those days in the 40s and 50s, steel fabricators and shipbuilders have made huge strides in conquering the problem of brittle fracture in ships. Shipyards use steel that is made specifically to be welded, steel that meets industry standards for what is called notch resistance. While no ship is or ever has been unsinkable, the men and women who now go to sea know that their ships are more seaworthy than ever.

Why I’m telling you this

Those who went to sea in metal ships in the early and mid-20th century brought to me and my family both safety and prosperity. Those big ore carriers on the Great Lakes kept the Ohio steel mills running all year long. The people and companies who worked in that industry fed tax money into the state system that paid for my education. Those tankers running between Gulf Coast and the Northeast brought with them the fuel oil that kept the homes of my relatives there warm in brutal winters. I owe those merchant mariners, doing work they knew could be extremely dangerous, an enormous debt of gratitude. That’s fundamentally why I / we here at The Mariners’ Museum tell these stories that connect us, all of us, together through the world’s waters. Profound respect and undying gratitude.