Hi everyone,

Kate and I wanted to share our progress with the wooden sides of the port gun carriage.

As mentioned before, we spent the last couple months mechanically cleaning the wood surface and we are happy to share that this cleaning phase is now completed!

Since the wood was located against iron for about 150 years before being disassembled from the carriage frame, its surface absorbed a lot of metallic salts. Along with iron staining, a solid corrosion “crust” was also partially covering the objects. The mechanical cleaning process required the use of small hand tools including compressed air tools to safely remove the material without damaging the waterlogged wood. We filmed about 5 seconds of surface cleaning with a dental ultrasonic scaler to give you an idea of how tedious and time consuming this cleaning process is:

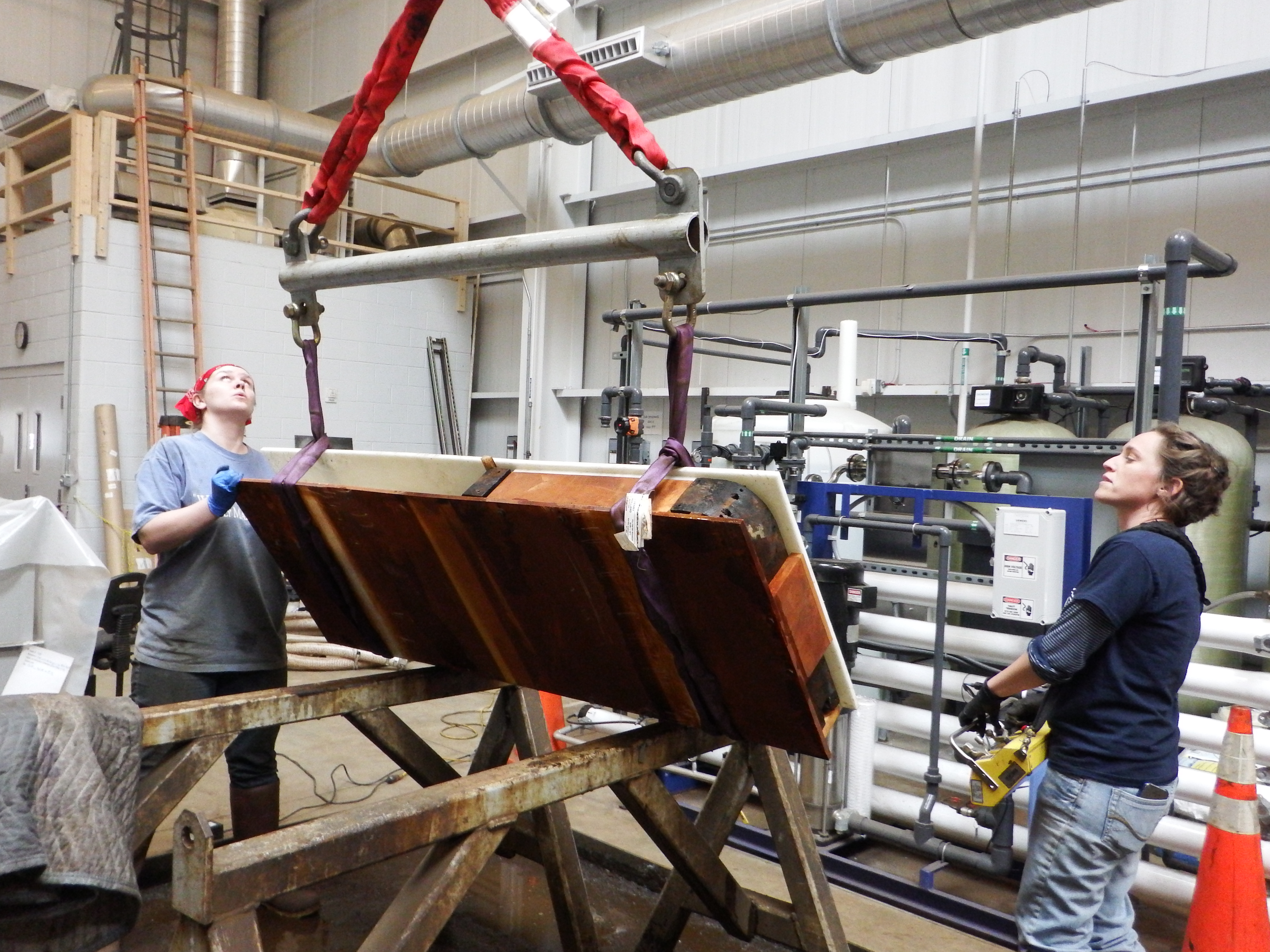

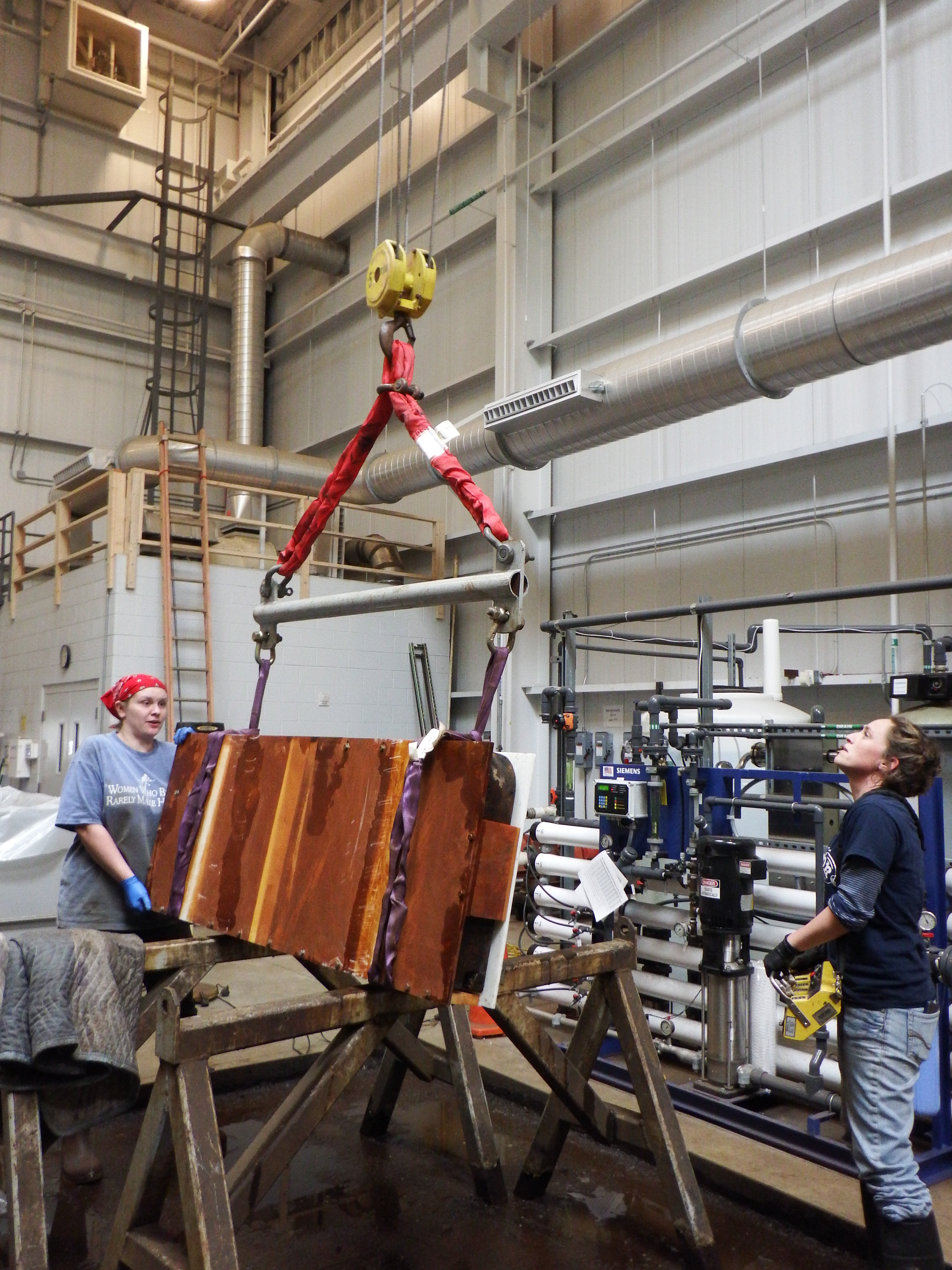

Another part of the job that might not be obvious is that flipping these wooden pieces around to clean them on both sides is quite a process! Each artifact weighs approximately 200lbs (supports included) and safely rotating them requires the use of a crane. Check it out:

And here is a “before”, “during” and “after” cleaning composite picture (respectively from top to bottom):

The cleaning job is however not quite finished yet. Unfortunately, in the long run, once the objects are dry and stable, the metallic salts contained in the wood could potentially be harmful to the artifacts if left within them (depending on the environmental conditions). As a result, after running a few tests, Kate and I also decided on a chemical cleaning solution that will help release the salts embedded deeper in the wood (see this blog for pictures of the tests). This chemical treatment of the wood is expected to take a while though, but this will allow us to focus our work on the metallic parts of the port gun carriage. These two wooden pieces are indeed two amongst 205 accession numbers (or parts) that were disassembled from this gun carriage. Some of these parts are already desalinated or in electrolytic reduction, but most of them are not. The dry ice cleaning method presented by Laurie last week will greatly improve the conservation treatment of the wrought iron elements and facilitate their desalination process. We are really excited about this and are looking forward to Laurie’s results on the efficiency of dry-ice blasting on copper alloys!

Only 203 more port gun carriage parts to go!!

Have a wonderful weekend!