On Wednesday, the removal of internal components from the Worthington pumps continued with the use of a hydraulic press and a tool specially made to apply even pressure to the brass water plungers in the pumps and push them out safely.

The port and starboard Worthingtons each had one of these plungers that worked back and forth to force water past one way valves in the upper part of the pump and out the discharge pipe. They moved freely in brass cylinder liners when the pump was in operation, so it was hoped that they would not be too difficult to push out, but after 149 years they were stuck and required some help.

When the tools were ready, the first water pump block was placed in the press and pressure was carefully applied. Very little effort was required and the plunger started moving!

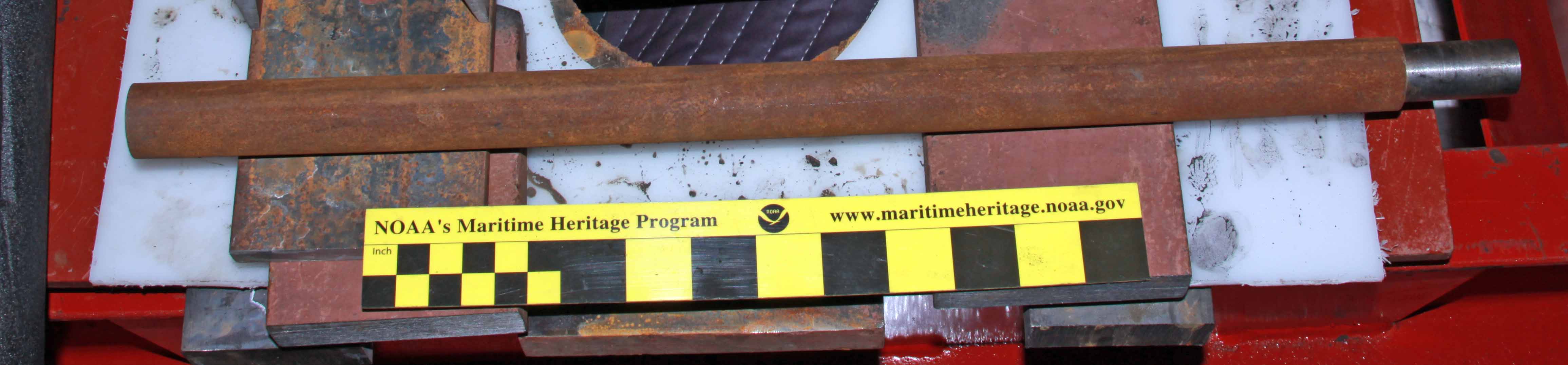

After a little more pushing, the plunger came out for the first time since 1862! The same operation was repeated for the starboard pump plunger with equal success.

This was a great day in the conservation process of the pumps. Hats off to Gary for a great rig!