“Rust never sleeps” was the title of an ICOM-CC conference dedicated to metals conservation in 2011; and it summarizes quite well why the conservation department cannot just leave the lab completely unattended during the current pandemic.

Not only are there a lot of electrochemical treatment set-ups that need constant attention in the “wet lab” and outdoor tanks, but environmental conditions in dry object storage also require our steadfast attention.

In the wet lab, twice a week, we perform manual check of the electrolytic reduction system of all tanks undergoing electrolysis. Although some are connected to a data collecting system, we still do a manual backup check. This allows us to catch poor electrical connections, deteriorations of reference electrodes, possible contacts where there shouldn’t be and address these issues quickly to protect the objects.

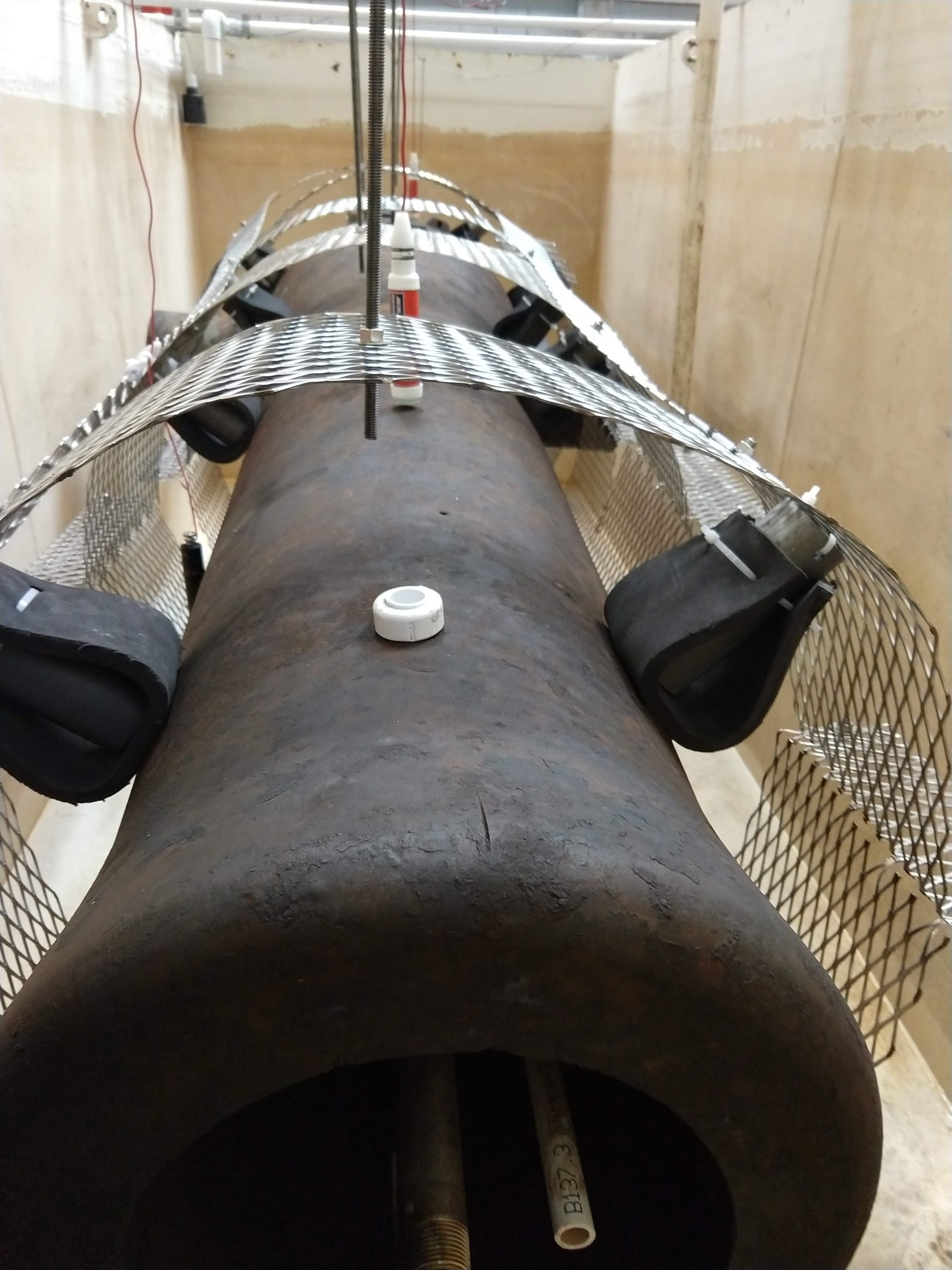

A major consideration immediately on the heels of the first days of quarantine was a new set-up of the electrolytic reduction system for both of the guns of USS Monitor. Major treatment steps had just been completed, boring the concretion from the gun barrels (more about the process here), and they had to return to desalination treatment to continue to remove the rust inducing salts that penetrate all materials on a salt-water wreck (see Erik’s blog). Even five months out we are still in the early days of observing how this treatment has accelerated the desalination of these objects. The combination of manual check of the electrolytic reduction systems, pH check, and automatically collected data every 5 seconds allows us to view how changes in the environment (thank you Tropical Storm Isaias…) impact our treatments and how our treatments work over time.

Periodic testing of the tank treatment solutions requires multiple staff and multiple days to complete a circuit of sampling, testing the samples, and data analysis, and combines in person work and remote work. These tests performed every two months allow us to determine immediate and long-term treatment decisions. Immediate decisions may be to switch the treatment solution, or to add additional chemicals to the treatment bath. Long-term treatment decisions may be to continue disassembly of a large object, to do dry-ice blasting to remove concretion, or to begin the final treatment steps and start drying the objects.

Other small tasks we perform twice a week in the wet lab are: verifying tank levels and topping them off if need be, fixing possible cracked containers or leaking tanks, and equipment inspections (crane, reverse osmosis system salts level, compressed air system…)

For USS Monitor artifacts that have completed conservation and are dry, as described by Lesley in her last blog, relative humidity (RH) surrounding artifacts is fundamental to the stability of their materials. In the same vein, some of you may remember the desiccant hammocks hanging in our Delta storage cabinets used to maintain a stable environment. Although these cabinets hold an excellent microenvironment, no seal is perfect, and we have to keep an eye on changes in RH inside over time. The desiccant (drying agent) we use to regulate the RH is a material called silica-gel which loses its efficiency over time as it absorbs moisture. It will eventually reach a point where it will no longer take up moisture which is referred to as being “exhausted”. Fortunately, we can “regenerate” the gel by drying it out in an oven. So, part of our weekly routine includes to switch out exhausted gel for regenerated material and setting the used gel in shallow baking pans and placing them in a scientific oven for about 8 hours at low temperature.

In addition to the permanent collection storage, reduced-staffing measures due to COVID-19 have meant that some treatments are currently paused, and associated objects placed in temporary controlled-storage until we can get back to them. Just like the storage cabinets (or even more so really!), these artifacts need to be checked periodically to ensure their microenvironments remain in tolerance.

Whether it is an immediate treatment decision, or a long-term treatment decision, we are vigilantly working to continue the conservation of these objects and ensure they are safe during these challenging times!