I have been meaning to write a blog about progress on the Monitor ropes but, although archaeological objects conservators are currently focused on this part of the collection, we do all sorts of other things that I thought would also be interesting to share with you.

If you have not done so yet, check out Laurie’s latest blogs about the gun sponge she has been treating lately. It looks so good!!

Brock also published a great blog about documentary photography tips recently in which we are seen sieving Monitor sediment from past cleaning campaigns (gun boring, condenser bed cleaning, nutguards cleaning…). Besides a few expected bolts, we made a couple neat finds in the sediment we went through. Stay tuned for another story that reveals what we found! For now, we are very pleased to report that we are up to date with sediment sieving from previous Monitor cleaning campaigns!

Something we seldom mention here is the time we spend doing maintenance on large tanks in the Wet Lab as well as in the “Tank Farm”. This summer, we took care of three large tanks located outside and two large tanks inside the Wet Lab. Maintenance means that we are changing the reference electrodes, cleaning the anodes if need be, checking all connections, sometimes rewiring, cleaning the (really) dirty tarps and renewing the alkaline solutions (each large tank requires 400lbs of caustic salts added to the water!). These are not the most glamorous activities we do but they are essential to the object’s conservation process.

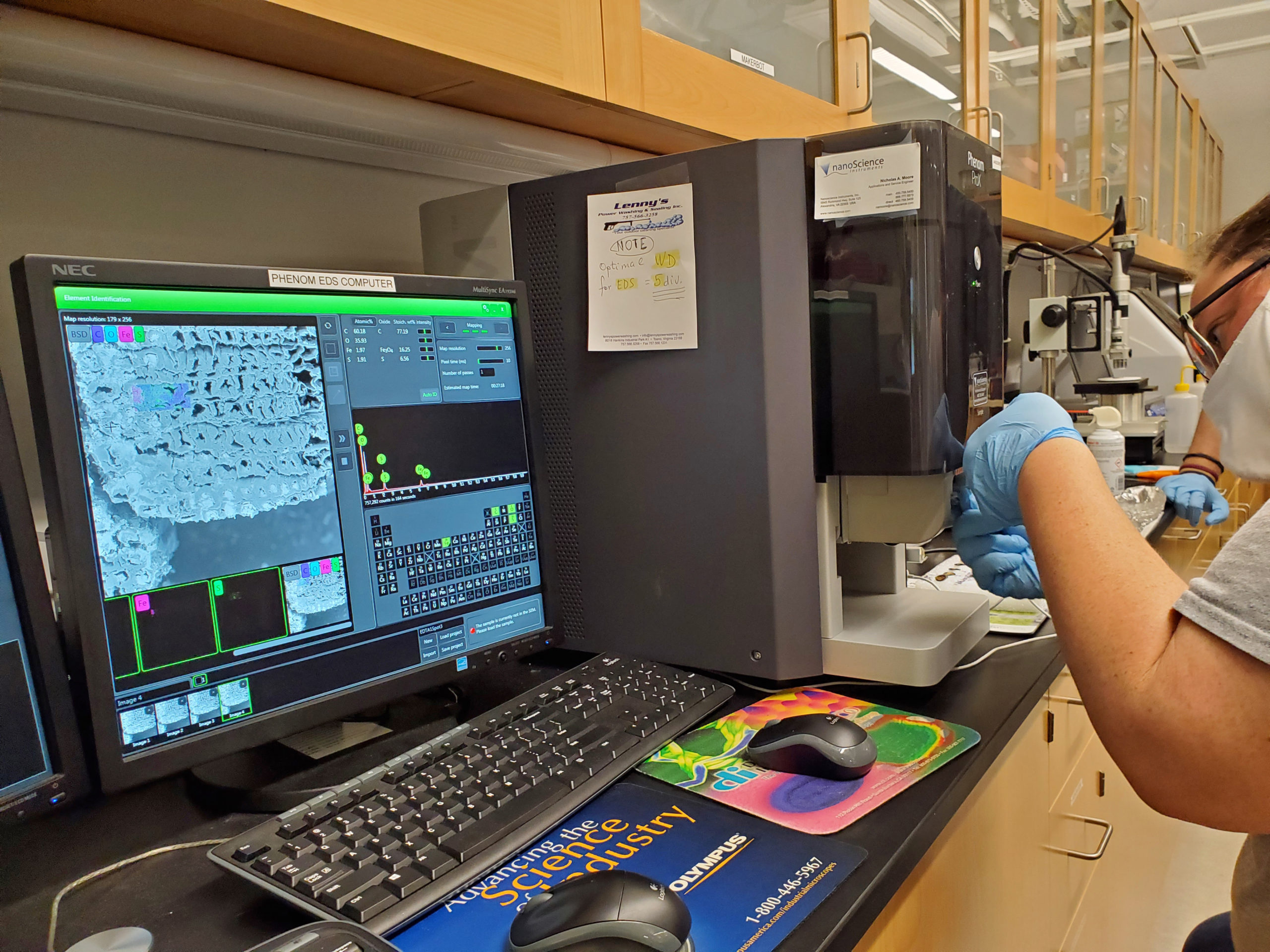

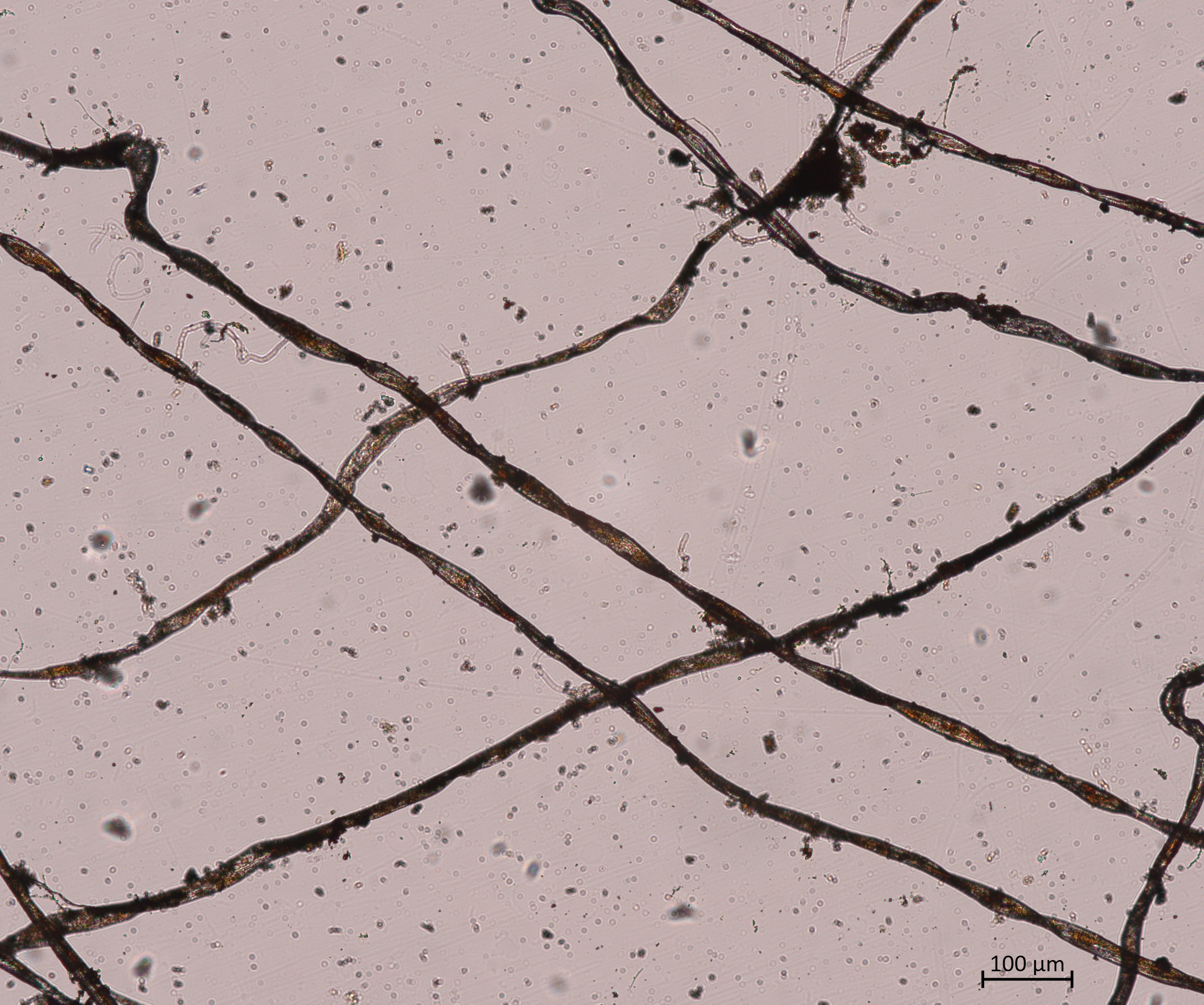

On the other side of the spectrum of what we do in the Lab, we have been working in conjunction with the Museum’s Associate Research Scientist Dr. Molly McGath on research projects. Molly and I have been continuing our work on finding the most adapted treatment to extract iron ions from waterlogged organics. We are trying to make sure that the damage happening to Princess Caroline timbers today will not happen to Monitor organics tomorrow (i.e. once dried). In other words, Kress Conservation Fellow, Christina Altland, has been looking into options to mitigate the problem once the damage was done on Princess Carolina timbers, and Molly and I are trying a preventative approach while the objects are still humid. For this purpose, we have been comparing treatment options of wooden samples under a very powerful microscope (Scanning Electron Microscope, aka SEM) at the Applied Research Center of William and Mary. Though we still have work to do for this project, we did get some interesting results in the past month.

Lesley, Laurie and Molly are also on a quest to best treat the many rubber gaskets recovered and detached from Monitor assemblies. They have been monitoring a sample of gaskets with a technique called Fourier Transform Infrared Spectroscopy while the gaskets are drying to identify possible degradation during this treatment phase.

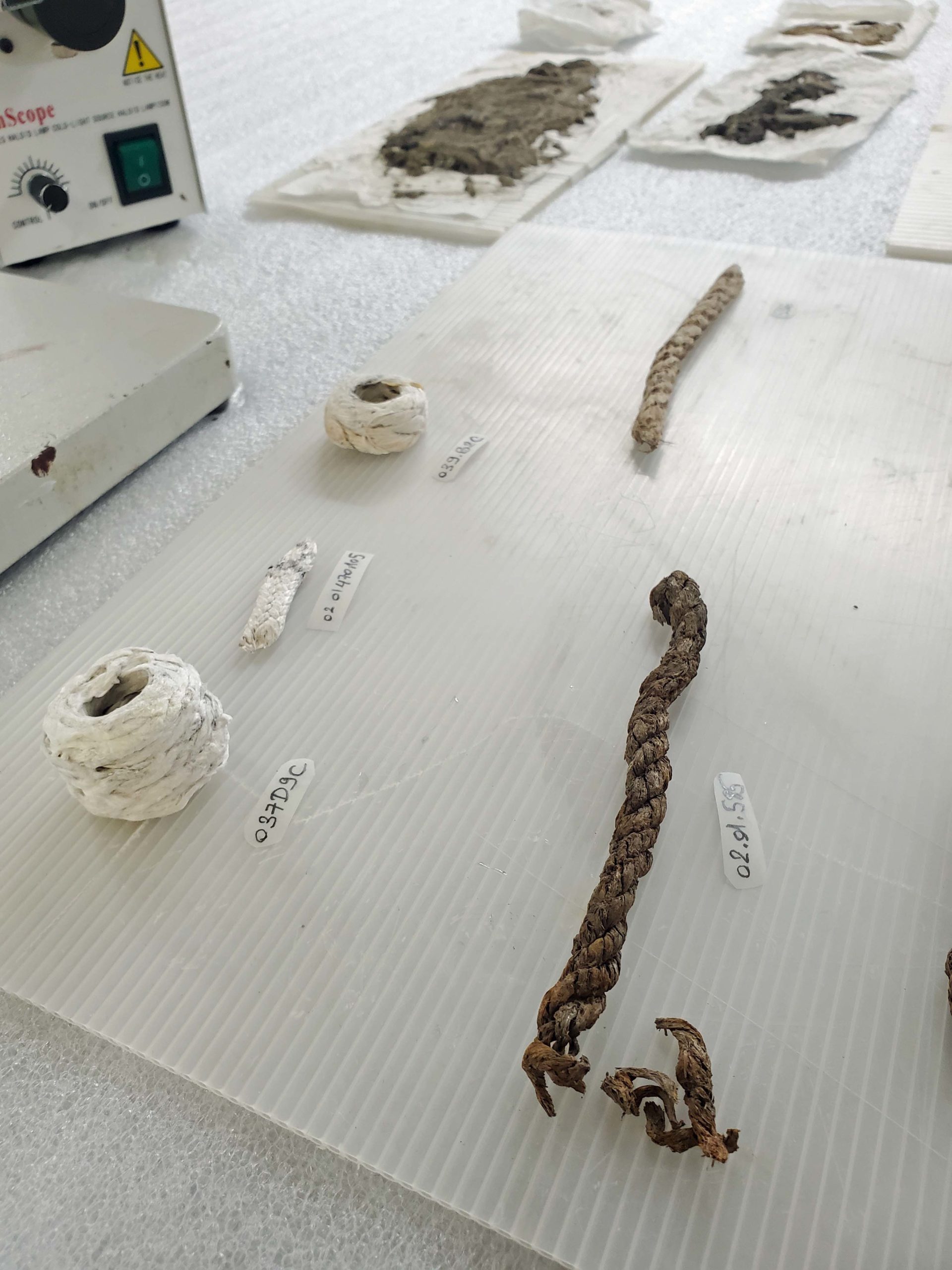

And of course, we are on a roll with the treatment of about 80 rope fragments and packing seal material from the shipwreck. Lesley and former conservator on staff Kate Sullivan did the background work for best practice on this specific collection and we started working on the smaller fragments last spring. As usual, a significant part of the job is to thoroughly document the objects, including identifying the fibers to hopefully be able to draw some interesting typology conclusion about this corpus down the line. Now that some of the smaller fragments have been fully treated, the objects are more substantial in size which is a nice change!

This week, the archaeological conservation team begins final disassembly work on Monitor’s condenser. For a refresher about this section of the ship, check this blog out. Within about a month, the condenser’s parts will be treated in a smaller tank, with a brand new treatment set up and solution. We look forward to this new milestone of the project!

Have a great week everyone!